Designing and building a hospital pharmacy needs careful planning for how it will work. We need to think about where it should be, how big it should be, and how people and things will move around in it.

The design should include places to keep important papers, a lot of supplies, special medicines, and things that need to be kept cold. We also need to plan for things like where the plumbing goes.

The pharmacy should have built-in storage, which means there are already places to keep things like paperwork, lots of supplies, medicines that need special care, and even medical gas tanks that can be moved.

We also need to make sure that there’s a good system for getting rid of things like water and waste from the pharmacy. This should be set up outside the building.

How the Pharmacy Building is Made

- Walls: The walls should be made of smooth material that doesn’t let water in, and they should be covered on both sides. Inside, the walls should be painted with a washable paint that stops mold, and outside, they should be painted with weatherproof paint. If there’s a special room for keeping things cold, its walls should be made of a special material to prevent water from forming on them.

- Floor: The floor should be made of concrete and made very smooth. The covering on the floor should be a tough material that doesn’t let things slip, even when there’s a lot of weight or movement. The floor should also not let water through, and it should be easy to clean. The height from the floor to the ceiling should be between 15 to 30 feet, depending on what the area is used for and what kind of equipment is used.

- Ceiling: The ceiling should be made of materials that don’t catch fire easily, and it should not have any asbestos. Asbestos is a material that can be harmful if it gets into the air. The ceiling should also not have any loose parts made of minerals.

- Roof: The roof should be slanted or sloped so that heavy rain doesn’t cause damage.

- Doors: The doors should be made of material that doesn’t catch fire easily. There should be two parts to the doors, and they should be wide enough for things to be moved in and out easily. If it’s a door used for exiting, it should be in a good place and have a bright sign showing where to go in case of an emergency.

- Windows: There should be windows where people are working, like at desks or in offices, but not in places where things are stored.

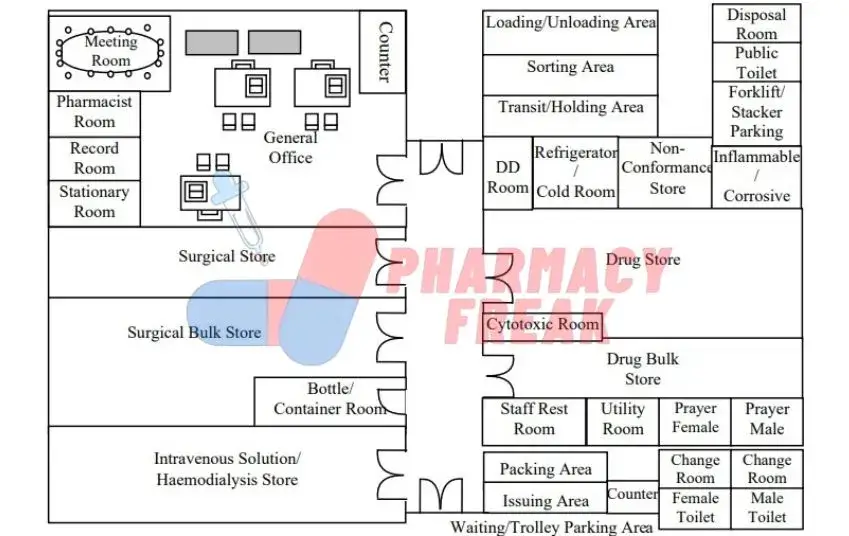

Receiving Area

- Loading and Unloading Area: This is the place where trucks bring in supplies. It needs to be big enough and have a roof to protect from weather, considering how tall the delivery trucks are.

- Receiving Counter: When supplies come in, there should be a counter where they are checked and signed for. This area needs space for people to wait and should have the right furniture and tools.

- Sorting and Unpacking Area: Once the supplies are in, there should be enough space to sort and check them. This area should be big enough for a forklift to be used.

- Transit/Holding Area: Some items might need more checking before they are accepted, or they might not need special storage. There should be a space for these things, including pallets.

- Disposal Room: This room is for things that are not needed anymore, like used boxes and wrappers.

Storage Area

- General Storage Requirement: The storage area should be kept at a certain temperature all the time. It should have special electrical connections to keep things like refrigerators and air conditioning working even if there’s a power failure. There should also be alarms if these machines stop working. There needs to be enough space for forklifts and other equipment, as well as IT facilities. Pallets, shelves, and racks should be there in good numbers.

- Drug Store: This is where medicines are stored. There should be adjustable racks for different-sized packages and a place for bigger items. Special plastic pallets should be there for bulk items. A section with clear warnings and a spill kit for dangerous drugs is necessary.

- Dangerous Drugs/Psychotropic Substances Store: This is a special room with a lock and an alarm for storing very strong medicines.

- Cold Room/Pharmaceutical Refrigerator/Freezer Area: Some medicines need to be kept very cold. This area is for storing these medicines. Each storage unit should have a system to record the temperature.

- Intravenous (IV) Fluid Store: This space is for solutions used in treatments like dialysis. It should be big enough for a forklift.

- Surgical Store: This is for storing a lot of surgical items. There should be adjustable racks and enough space for big items.

- Non-Drug Bulk Store: This area is for storing things like bottles, containers, labels, and envelopes. It should have adjustable racks and enough space for easy movement.

Store with Special Requirement

- 1) Inflammable Store: This area should be located at a minimum of 10 feet distance away from other adjacent buildings. It should be designed for storing inflammable items (ethanol, methanol, acetone, etc.) and should be equipped with firefighting equipment, smoke detectors, and exhaust fans for proper ventilation. The location and design of the inflammable store should provide maximum air circulation so that accumulation of fumes or gases can be avoided. Spark-proof switches should be present outside the room.

- 2) Corrosive Items Store: This area should be designed for the storage of corrosive items ( such as phenols and hypochlorite). It should be equipped with a special plumbing and drainage system and an eye wash station.

- 3) Medical Gas Store: This area should be designed for the storage of portable medical gas cylinders. The floor should be reinforced to bear the weight of heavy gas cylinders. Loading and unloading areas should be made present and sheltered well. The bay should be constructed to enable direct loading and unloading of goods. All electrical facilities should fulfill the requirements of the Fire Fighting and Rescue Departments and the Department of Environment. Proper ventilation should be maintained.

- 4) Quarantined Item Store: A designated area or cabinet should be provided and clearly labeled.

- 5) Non-Conformance/Condemned Item Store: A designated store/cabinet for expired, obsolete, or damaged items should be provided before disposal.

Issuing Area

- Temporary Holding Area: This is where supplies are prepared for different departments. Requests from different departments are processed here until they are picked up. There should be secure areas nearby.

- Issuing Counter: This counter is where the prepared supplies are given out. It needs to have enough space for people to wait and should have the right furniture. There should also be space for handling equipment.

Administrative Area

- Pharmacist In-Charge Office: This is the office for the head pharmacist to do administrative work. It should be placed so that supervision is easy.

- Pharmacist Work Station: This is the area for pharmacists to work. It should have glass panels for supervision, and there should be workstations and computer terminals.

- General Office: This area is for assistant administrative officers and administrative assistants. It should have workstations with computer terminals.

- Meeting/Discussion Room: This is a space for meetings and routine administrative discussions. It needs to have enough space for these activities.

- Document Room: This room is for storing files and records. There should be enough space for all the documents.

- Reception Counter and Customer Waiting Area: This is where customers are received. The waiting area should have the right furniture and facilities like audio-visual equipment, a water dispenser, and comfortable seating.

Ancillary Area

- Personnel/Staff Rest Room: This room is for the staff to take breaks. It should have lockers and basic appliances like a refrigerator, electric kettle, water dispenser, microwave oven, and comfortable furniture.

- Wash Room: Separate washrooms for males and females, including changing rooms, toilets, and showers. There should also be a dedicated toilet for visitors.

- Housekeeping/Utility Room: This room is for storing cleaning materials and equipment. It needs good ventilation for washing and drying equipment.

- Security Guard Post: This is where the security guard stays, usually at the main entrance. The room should have the necessary equipment for the convenience of the security guard.

Floor Space Requirements

The space needed for a hospital pharmacy depends on various factors like the scale of operations, the variety of medications, patient load (for outpatient pharmacies), the number of inpatients, and the pharmacy staff size. According to the Drugs and Cosmetics Act (under Schedule M), the minimum floor area should be 250 sq m. For larger hospitals, the area requirement increases, with 10 sq m per bed for 100 beds, 6 sq m per bed for 200 beds, and at least 5 sq m per bed for more extensive hospitals. Teaching institutes usually demand even more space.

Staff Requirements

The structure of a hospital pharmacy varies, including departments like dispensing, medical stores, manufacturing, quality control, and clinical pharmacy. Staffing depends on factors such as the number of beds, service to outpatients and inpatients, involvement in drug manufacturing, and stocking and dispensing of surgical and laboratory supplies. The essential staff includes:

- Chief Pharmacist or Director: One member, usually with a postgraduate degree in pharmacy, preferably in pharmacology or hospital pharmacy.

- Registered Pharmacists: At least four in smaller hospitals to handle around 60 patients each. The total number of patients, both inpatients and outpatients, determines staffing.

- Support Staff: Adequate assistants, attendants, and sweepers.

- Pharmacist-cum-Clerk or Clerks: Depending on the hospital’s size.

- Manufacturing and Analytical Chemists: Hospitals involved in drug manufacturing should have these professionals with relevant qualifications and experience.

- Pharmacists as per Bed Capacity: For different bed capacities, the number of pharmacists varies, e.g., for a 50-bedded hospital, three pharmacists are needed, and in more extensive hospitals, one pharmacist for every 133 patients is recommended.

Qualifications

- Chief Pharmacist or Director: Postgraduate degree holder in pharmacy, preferably in pharmacology or hospital pharmacy.

- Manufacturing Chemist: Pharmacy graduate with a minimum of 18 months of experience in manufacturing drugs and formulations.

- Analytical Chemist: Postgraduate in pharmaceutical chemistry or analytical chemistry.

- Registered Pharmacists and Pharmacists-cum-Clerk: Diploma in pharmacy and registration in the state pharmacy council.

Reference

- Science Direct- Hospital Pharmacy

- Wikipedia- Hospital pharmacy

Related Links

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com

I have some land 20 meters by 42 meters across the street from the main hospital Axochiapan Mexico ….would that be a good location to build a pharmacy building to rent out ?