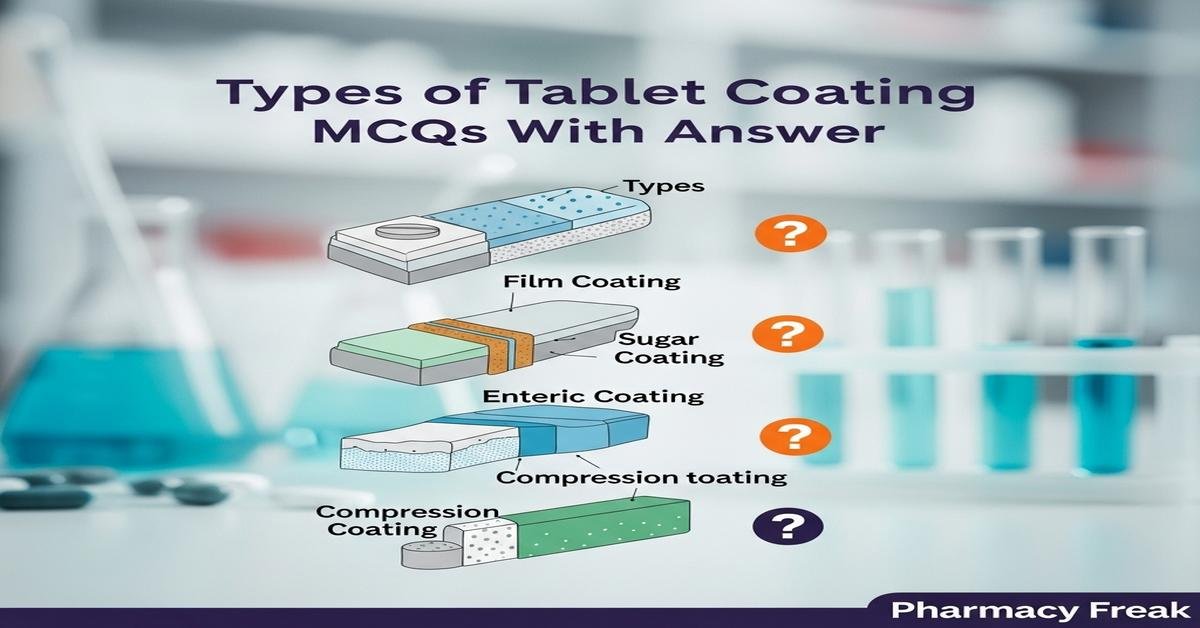

Tablet coating is a vital area in pharmaceutics that impacts drug stability, controlled release, patient compliance, and manufacturability. This introduction for B. Pharm students explores major types of tablet coating — sugar coating, film coating, enteric coating, and polymeric seal coats — while addressing coating polymers (HPMC, EC, Eudragit), plasticizers, solvents (aqueous vs organic), equipment (coating pans, perforated pans, fluidized bed), and critical process parameters. Emphasis on mechanism of action, formulation variables, common defects, and quality control tests (weight gain, disintegration, dissolution) strengthens both theory and practical troubleshooting skills. Now let’s test your knowledge with 30 MCQs on this topic.

Q1. What is the primary advantage of film coating compared to sugar coating?

- Faster production and thinner coat

- Better taste masking than sugar coat

- Uses only organic solvents

- Always produces enteric properties

Correct Answer: Faster production and thinner coat

Q2. Which polymer is commonly used for enteric coating to prevent drug release in the stomach?

- Hydroxypropyl methylcellulose (HPMC)

- Ethylcellulose (EC)

- Eudragit L (methacrylic acid copolymer)

- Povidone (PVP)

Correct Answer: Eudragit L (methacrylic acid copolymer)

Q3. Which parameter most directly affects droplet size during spray coating?

- Inlet air temperature

- Atomization air pressure (or nozzle pressure)

- Tablet hardness

- Coating pan speed

Correct Answer: Atomization air pressure (or nozzle pressure)

Q4. Which coating defect is characterized by rough, sandpaper-like tablet surface due to rapid solvent evaporation?

- Picking

- Mottling

- Orange peel

- Bridging

Correct Answer: Orange peel

Q5. What is the role of plasticizers in film coating formulations?

- Act as primary film former

- Reduce glass transition temperature and increase film flexibility

- Increase tablet porosity

- Enhance tablet disintegration

Correct Answer: Reduce glass transition temperature and increase film flexibility

Q6. Which solvent type is preferred for most modern film coatings due to safety and environmental concerns?

- Chlorinated organic solvents

- Aqueous (water-based) systems

- Pure ethanol systems only

- Methylene chloride

Correct Answer: Aqueous (water-based) systems

Q7. A target coating weight gain for a typical film-coated immediate-release tablet is usually expressed as:

- 0.1–0.5% w/w

- 1–3% w/w

- 10–20% w/w

- 50–100% w/w

Correct Answer: 1–3% w/w

Q8. Which additive provides opacity and white color in many coating formulations?

- Titanium dioxide

- Sorbitol

- Glycerin

- Magnesium stearate

Correct Answer: Titanium dioxide

Q9. During enteric coating, disintegration testing should show no disintegration in:

- pH 1.2 (simulated gastric fluid) for a specified time

- pH 6.8 for 5 minutes

- pH 7.4 only

- Distilled water at 25°C

Correct Answer: pH 1.2 (simulated gastric fluid) for a specified time

Q10. Which coating technique is best suited for very high-volume industrial coating with efficient solvent recovery?

- Dip coating

- Conventional coating pan without perforations

- Perforated coating pan (high-efficiency)

- Hand spraying

Correct Answer: Perforated coating pan (high-efficiency)

Q11. Which polymer is commonly used for sustained-release coating because it is water-insoluble but permeable?

- Hydroxypropyl methylcellulose (HPMC)

- Ethylcellulose (EC)

- Eudragit L

- Polyvinyl alcohol (PVA)

Correct Answer: Ethylcellulose (EC)

Q12. Mottling in coated tablets is most often caused by:

- Uniform pigment distribution

- Non-uniform distribution of dye/pigment and substrate interaction

- Excessive coating weight gain

- Use of plasticizers

Correct Answer: Non-uniform distribution of dye/pigment and substrate interaction

Q13. Which test directly assesses coating uniformity across a batch of tablets?

- Friability test

- Hardness test

- Weight variation of coated tablets

- Moisture content only

Correct Answer: Weight variation of coated tablets

Q14. Which coating defect is characterized by tablets sticking together or adhering to the pan?

- Blistering

- Sticking and picking

- Pitting

- Peeling

Correct Answer: Sticking and picking

Q15. Which factor is least likely to cause cracking of the coating film?

- Excessive plasticizer content

- Rapid drying and brittle film formation

- Low elasticity of the film former

- Large film thickness without proper formulation

Correct Answer: Excessive plasticizer content

Q16. Which analytical method is commonly used to determine coating thickness on tablets?

- UV-visible spectroscopy of intact tablet

- Destructive cross-sectioning with microscopy

- pH titration of the coat

- Friability testing

Correct Answer: Destructive cross-sectioning with microscopy

Q17. For taste masking of bitter drugs, which coating approach is most suitable for immediate release but preventing taste in the mouth?

- Enteric coating that dissolves in the stomach

- Thin polymeric barrier coating that dissolves in the stomach but not in saliva

- Sugar coating that dissolves in the mouth

- No coating — use higher dose

Correct Answer: Thin polymeric barrier coating that dissolves in the stomach but not in saliva

Q18. Curing of coated tablets is performed to:

- Reduce tablet hardness

- Promote film coalescence and improve mechanical strength

- Remove all plasticizers

- Increase dissolution rate drastically

Correct Answer: Promote film coalescence and improve mechanical strength

Q19. What effect does increasing inlet air temperature generally have on the coating process (assuming other parameters constant)?

- Slows solvent evaporation

- Speeds solvent evaporation and may increase risk of orange peel

- Has no effect on drying

- Always improves coating gloss without risk

Correct Answer: Speeds solvent evaporation and may increase risk of orange peel

Q20. Which excipient is often added to coating dispersions to improve adhesion between coat and tablet core?

- Release-retardant polymer only

- Wetting agents or surfactants

- Magnesium stearate

- Talc at high concentration

Correct Answer: Wetting agents or surfactants

Q21. A common challenge when switching from organic to aqueous coating systems is:

- Faster drying rates in aqueous systems

- Higher toxicity of aqueous systems

- Longer drying times and potential for core moisture uptake

- Inability to incorporate pigments

Correct Answer: Longer drying times and potential for core moisture uptake

Q22. Which of the following Eudragit types is commonly used for sustained release by pH-independent insoluble film formation?

- Eudragit L (anionic, pH-dependent soluble)

- Eudragit S (pH-dependent soluble)

- Eudragit RS (cationic, controlled permeability)

- Eudragit E (basic pH soluble)

Correct Answer: Eudragit RS (cationic, controlled permeability)

Q23. Which coating defect indicates gas formation beneath the coat, often seen as blisters?

- Pilling

- Blistering

- Mottling

- Polishing

Correct Answer: Blistering

Q24. In a fluidized bed coating, the bed material is suspended by:

- Rotational motion of a pan

- Upward airflow through the bed

- Magnetic stirring

- High temperature alone

Correct Answer: Upward airflow through the bed

Q25. Which property of a coating polymer most influences its film-forming capability at given processing temperatures?

- Molecular weight only

- Glass transition temperature (Tg)

- pKa of polymer

- Color of polymer

Correct Answer: Glass transition temperature (Tg)

Q26. Which quality control test assesses the ability of the coated tablet to withstand mechanical shocks during handling?

- Dissolution test

- Friability test

- Disintegration test

- Assay by HPLC

Correct Answer: Friability test

Q27. Which coating defect results from excessive spray solution causing formation of islands or lumps on the surface?

- Bridging

- Pilling

- Roughness and agglomeration

- Discoloration only

Correct Answer: Roughness and agglomeration

Q28. When designing an enteric-coated tablet, the critical pH at which polymer should dissolve is typically above:

- pH 1.5

- pH 3.5

- pH 5.5–6.0

- pH 9.0

Correct Answer: pH 5.5–6.0

Q29. Which excipient is commonly used as a glidant and anti-tacking agent in coating formulations?

- Talc

- Sucrose

- HPMC

- PVP K30

Correct Answer: Talc

Q30. For targeted colonic drug delivery using coating, which strategy may be employed?

- Use of immediate-release sugar coating

- Use of pH-sensitive polymers alone without consideration of transit time

- Use of time-dependent and/or microbially degradable coatings with pH-triggered layers

- Use of highly water-soluble film formers only

Correct Answer: Use of time-dependent and/or microbially degradable coatings with pH-triggered layers

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com