Silverson emulsifier – principle, construction, working, uses, merits, demerits MCQs With Answer

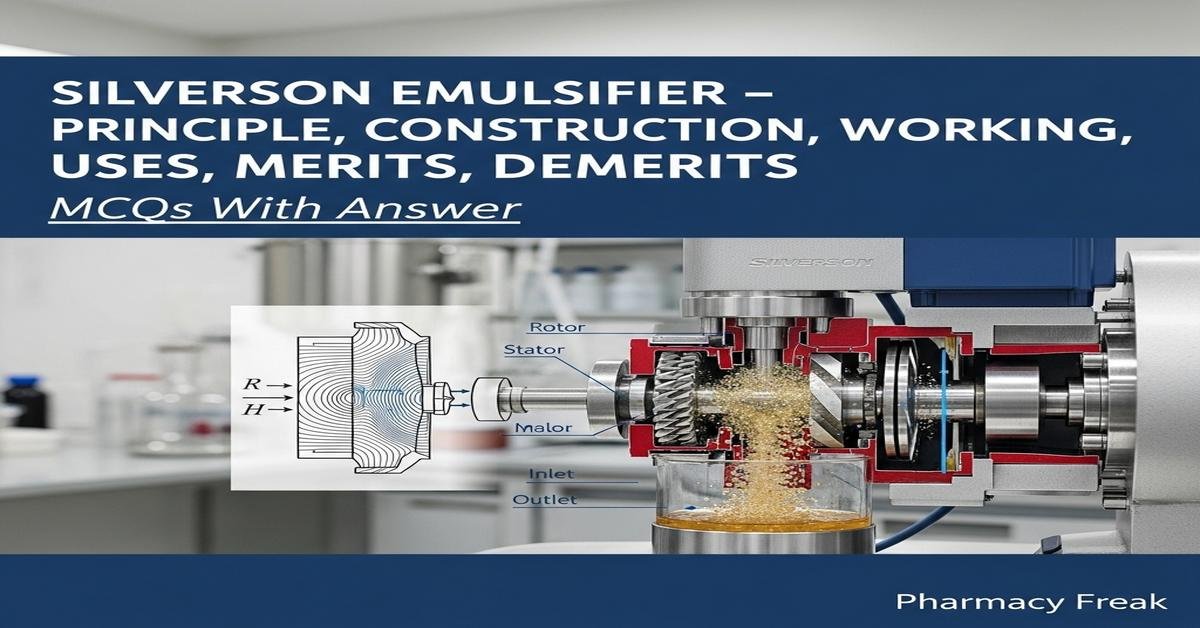

Silverson emulsifier is a high-shear rotor-stator homogenizer widely used in pharmaceutical formulation for producing stable emulsions and dispersions. This introduction covers the principle of shear and cavitation, detailed construction of rotor, stator and drive, working parameters (speed, time, temperature), pharmaceutical uses, merits like narrow droplet size and scalability, and demerits such as heat generation and maintenance needs. Designed for B. Pharm students, the content links theory to practice: factors affecting droplet size, surfactant selection, batch versus continuous operation, cleaning and validation, and troubleshooting. Keyword-rich and exam-focused, this guide prepares you for practical application and MCQs. Now let’s test your knowledge with 50 MCQs on this topic.

Q1. What is the primary working principle of a Silverson emulsifier?

- Diffusion-driven mixing

- High-shear rotor-stator action producing shear and cavitation

- Magnetic stirring

- Thermal convection

Correct Answer: High-shear rotor-stator action producing shear and cavitation

Q2. The main moving component that generates shear in a Silverson emulsifier is the:

- Stator plate

- Rotor (impeller)

- Feed pump

- Heating jacket

Correct Answer: Rotor (impeller)

Q3. In a rotor-stator assembly, the stator primarily functions to:

- Heat the product

- Provide stationary openings to intensify shear and control flow

- Pump the emulsion to storage

- Measure viscosity

Correct Answer: Provide stationary openings to intensify shear and control flow

Q4. Which factor most directly reduces emulsion droplet size in Silverson processing?

- Lower rotor speed

- Higher shear rate and shorter gap between rotor and stator

- Longer storage time after mixing

- Using distilled water instead of formulation water

Correct Answer: Higher shear rate and shorter gap between rotor and stator

Q5. Which parameter is critical to control heat generation during high-shear emulsification?

- Rotor material only

- Mixing speed, processing time, and cooling (temperature control)

- Color of the vessel

- Ambient humidity

Correct Answer: Mixing speed, processing time, and cooling (temperature control)

Q6. The Silverson batch head is typically used for:

- Continuous inline production only

- Small to medium batch emulsification and dispersion

- Sterilization of equipment

- Packaging finished product

Correct Answer: Small to medium batch emulsification and dispersion

Q7. Which phenomenon produced by rotor-stator action contributes to droplet breakup besides shear?

- Diffraction

- Cavitation and turbulence

- Osmosis

- Gravitational settling

Correct Answer: Cavitation and turbulence

Q8. For pharmaceutical emulsions, surfactant selection affects:

- Only color of the emulsion

- Interfacial tension, stability, and droplet size distribution

- Magnetic properties

- Stator rotation speed

Correct Answer: Interfacial tension, stability, and droplet size distribution

Q9. Which operational mode of Silverson is preferred when integrating with upstream and downstream processes?

- Manual batch stirring

- Inline continuous mode

- Static mixing only

- Open-air sprinkling

Correct Answer: Inline continuous mode

Q10. A common advantage of Silverson emulsifiers in pharma formulation is:

- Unlimited product heating

- Ability to produce a narrow, controlled droplet size distribution

- Elimination of surfactants

- Permanent magnetic alignment of particles

Correct Answer: Ability to produce a narrow, controlled droplet size distribution

Q11. Excessive processing time in a Silverson can lead to:

- Complete sterilization

- Overheating, ingredient degradation, and potential re-coalescence

- Decreased viscosity due to polymerization

- Increased particle magnetization

Correct Answer: Overheating, ingredient degradation, and potential re-coalescence

Q12. Which design feature helps reduce maintenance frequency of a Silverson emulsifier?

- Using a single-use rotor

- Choosing robust materials like stainless steel and easy-to-remove rotor-stator elements

- Sealing rotors permanently

- Omitting seals entirely

Correct Answer: Choosing robust materials like stainless steel and easy-to-remove rotor-stator elements

Q13. In scale-up from lab to production, which similarity is most important to maintain?

- Exact vessel color

- Power per unit volume or equivalent tip speed and shear energy

- Same operator

- Same room humidity

Correct Answer: Power per unit volume or equivalent tip speed and shear energy

Q14. Which cleaning consideration is important for pharmaceutical Silverson emulsifiers?

- No cleaning required between batches

- Design for Clean-In-Place (CIP) and material compatibility with cleaning agents

- Use of abrasive cleaners always

- Only rinsing with organic solvent

Correct Answer: Design for Clean-In-Place (CIP) and material compatibility with cleaning agents

Q15. What is the effect of increasing rotor speed on emulsion formation, assuming other parameters constant?

- Increases shear leading to smaller droplets up to a limit

- Always increases droplet size

- No effect on droplet size

- Causes immediate solidification

Correct Answer: Increases shear leading to smaller droplets up to a limit

Q16. A Silverson emulsifier can process highly viscous systems best when equipped with:

- Smaller rotor-stator gaps and high-torque motor

- Very thin stator only

- Low torque and high speed only

- Plastic rotors

Correct Answer: Smaller rotor-stator gaps and high-torque motor

Q17. What is a common demerit of high-shear Silverson emulsification in pharmaceuticals?

- Universal removal of air bubbles

- Heat generation and possible degradation of heat-sensitive actives

- No mixing capability

- Guaranteed sterilization

Correct Answer: Heat generation and possible degradation of heat-sensitive actives

Q18. Which measurement assesses the emulsifier’s performance in producing fine droplets?

- pH only

- Droplet size distribution (e.g., D50) and polydispersity

- Color index

- Electrical conductivity only

Correct Answer: Droplet size distribution (e.g., D50) and polydispersity

Q19. The term “tip speed” refers to:

- Speed of sampling the product

- Linear speed at the rotor edge, important for shear generation

- Speed of the operator moving around the machine

- Speed of the feed pump only

Correct Answer: Linear speed at the rotor edge, important for shear generation

Q20. For water-in-oil (W/O) vs oil-in-water (O/W) emulsions, Silverson performance depends on:

- Only rotor material

- Formulation composition, surfactant HLB and process energy

- Color of the oil phase

- Ambient light

Correct Answer: Formulation composition, surfactant HLB and process energy

Q21. Which part often requires periodic replacement due to wear in Silverson machines?

- Frame feet

- Rotor and stator inserts

- Motor casing paint

- Electrical cable only

Correct Answer: Rotor and stator inserts

Q22. In an inline Silverson system, residence time primarily affects:

- Only the color of the emulsion

- Degree of emulsification and droplet size reduction

- Electrical consumption exclusively

- Ambient room temperature

Correct Answer: Degree of emulsification and droplet size reduction

Q23. The term “shear rate” in rotor-stator mixing is best described as:

- Rate of solvent evaporation

- Velocity gradient between fluid layers that causes deformation and breakup

- Number of rotations per batch

- Temperature change per minute

Correct Answer: Velocity gradient between fluid layers that causes deformation and breakup

Q24. Which cleaning validation concern is unique to Silverson emulsifiers in pharma?

- Cross-contamination from residual emulsifiers/surfactants requiring validated CIP

- Only external cleaning is needed

- Cleaning increases droplet size

- Cleaning cannot remove oils

Correct Answer: Cross-contamination from residual emulsifiers/surfactants requiring validated CIP

Q25. When formulating emulsions with sensitive actives, a mitigation strategy is to:

- Increase processing temperature

- Optimize speed/time, use cooling, and consider gentler pre-emulsification

- Add more abrasive particles

- Use open flame heating

Correct Answer: Optimize speed/time, use cooling, and consider gentler pre-emulsification

Q26. Which material is commonly used for Silverson rotors and stators in pharmaceutical applications?

- Iron with rust coating

- Stainless steel (e.g., 316L) for corrosion resistance and cleanliness

- Wood

- Plain carbon steel without finish

Correct Answer: Stainless steel (e.g., 316L) for corrosion resistance and cleanliness

Q27. What role does surfactant HLB play in emulsification with a Silverson?

- Determines the color of the product

- Indicates hydrophilic-lipophilic balance guiding O/W or W/O formation and stability

- Controls motor speed

- Changes rotor geometry

Correct Answer: Indicates hydrophilic-lipophilic balance guiding O/W or W/O formation and stability

Q28. Which test helps evaluate emulsion stability over time?

- Viscometry, centrifugation, and accelerated stability testing

- Only smell test

- Counting bubbles visually

- Measuring magnetic susceptibility

Correct Answer: Viscometry, centrifugation, and accelerated stability testing

Q29. Cavitation in Silverson emulsification can be advantageous because it:

- Produces cooling

- Generates intense local shear aiding droplet breakup

- Prevents emulsification

- Raises pH

Correct Answer: Generates intense local shear aiding droplet breakup

Q30. Which parameter is least likely to influence droplet size in a Silverson system?

- Rotor speed

- Interfacial tension

- Atmospheric pressure at sea level in typical labs

- Processing time

Correct Answer: Atmospheric pressure at sea level in typical labs

Q31. Which advantage does inline Silverson emulsification offer over traditional batch stirring?

- Higher variability between batches

- Better process control, reproducibility, and easier scale-up

- Less control of residence time

- Impossible to integrate with CIP

Correct Answer: Better process control, reproducibility, and easier scale-up

Q32. The term D90 in droplet size analysis means:

- 90th percentile droplet size below which 90% of particles fall

- Droplet size at 90 RPM

- Diameter multiplied by 90

- Time required to reach 90% mixing

Correct Answer: 90th percentile droplet size below which 90% of particles fall

Q33. Which operational change can reduce foaming during Silverson emulsification?

- Increase speed without additives

- Use defoamers, reduce air entrainment and optimize immersion depth

- Increase headspace and shake vigorously

- Open the vessel to sunlight

Correct Answer: Use defoamers, reduce air entrainment and optimize immersion depth

Q34. In pharmaceutical process validation, a critical quality attribute (CQA) related to Silverson emulsification is:

- Operator shoe size

- Mean droplet size and emulsion stability

- Color of the mixing head cover

- Type of flooring in the plant

Correct Answer: Mean droplet size and emulsion stability

Q35. Which type of formulation is commonly prepared using a Silverson emulsifier in pharmacy?

- Tablets by direct compression only

- Topical creams, lotions, and parenteral lipid emulsions

- Lyophilized powders exclusively

- Solid oral dosage forms that do not require dispersion

Correct Answer: Topical creams, lotions, and parenteral lipid emulsions

Q36. What is the effect of increased viscosity of the continuous phase on emulsification?

- Improves droplet breakup regardless of energy input

- May hinder droplet breakup and require higher shear or longer processing

- Eliminates need for surfactant

- Always causes phase inversion

Correct Answer: May hinder droplet breakup and require higher shear or longer processing

Q37. Which rotor geometry change can increase shear intensity?

- Increasing rotor diameter and maintaining high RPM to raise tip speed

- Using a blunt, very slow rotor

- Removing rotor teeth entirely

- Using a larger stator gap only

Correct Answer: Increasing rotor diameter and maintaining high RPM to raise tip speed

Q38. Which sampling practice is important during process optimization with a Silverson?

- Never sample during processing

- Take time-point samples to monitor droplet size, viscosity, and temperature

- Only sample at the beginning of the day

- Sampling only after 24 hours

Correct Answer: Take time-point samples to monitor droplet size, viscosity, and temperature

Q39. Which maintenance action extends the life of rotor-stator parts?

- Using corrosive cleaners regularly

- Routine inspection, balanced operation, and replacement when worn

- Running at maximum speed constantly

- Grinding the rotor on-site to fit

Correct Answer: Routine inspection, balanced operation, and replacement when worn

Q40. Phase inversion during emulsification occurs when:

- Continuous and dispersed phases swap roles due to composition or energy changes

- The rotor stops completely

- Ambient light causes color change

- Temperature drops below freezing only

Correct Answer: Continuous and dispersed phases swap roles due to composition or energy changes

Q41. Which analytical technique is commonly used to quantify droplet size distribution?

- UV-visible spectroscopy only

- Laser diffraction or dynamic light scattering

- pH meter

- Rotary evaporator

Correct Answer: Laser diffraction or dynamic light scattering

Q42. Which practice minimizes contamination risk during processing?

- Open vessel processing without PPE

- Closed system processing, CIP, and following aseptic procedures when required

- Using unvalidated cleaning agents

- Allowing outdoor air into the mixing vessel

Correct Answer: Closed system processing, CIP, and following aseptic procedures when required

Q43. When emulsifying oil droplets at very low concentrations, which issue may arise?

- Droplet size analysis becomes easier

- Difficulty detecting and measuring droplets; sampling bias

- Automatic phase inversion

- Viscosity becomes zero

Correct Answer: Difficulty detecting and measuring droplets; sampling bias

Q44. Which energy-related metric is useful for comparing emulsification processes?

- Energy input per unit mass or power per unit volume (kW/m3)

- Only the motor brand

- Length of the power cord

- Color of rotor paint

Correct Answer: Energy input per unit mass or power per unit volume (kW/m3)

Q45. For a thermolabile drug in an emulsion, best practice is to:

- Increase rotor speed and temperature

- Minimize dwell time, use cooling, and consider gentler homogenization steps

- Exclude surfactant completely

- Heat above decomposition point

Correct Answer: Minimize dwell time, use cooling, and consider gentler homogenization steps

Q46. Which operational change can improve reproducibility between batches?

- Varying rotor speed randomly

- Standardizing feed rates, speeds, temperatures and sampling protocols

- Changing surfactant each batch

- Operating without record keeping

Correct Answer: Standardizing feed rates, speeds, temperatures and sampling protocols

Q47. Why is rotor-stator gap critical in Silverson design?

- It has no effect on mixing

- A smaller gap increases shear intensity and improves droplet breakup

- Larger gaps always produce smaller droplets

- Gap only affects electrical consumption

Correct Answer: A smaller gap increases shear intensity and improves droplet breakup

Q48. When developing a new emulsion, an initial step before high-shear processing is to:

- Skip pre-mixing and go direct to high shear

- Pre-emulsify by low-shear mixing to create a coarse emulsion

- Freeze the ingredients

- Vaporize the oil phase

Correct Answer: Pre-emulsify by low-shear mixing to create a coarse emulsion

Q49. Which safety consideration is specific to Silverson operation?

- Ensure electrical interlocks, guard rotating parts, and avoid run-dry conditions

- No PPE required

- Operate open flames nearby

- Disable emergency stops

Correct Answer: Ensure electrical interlocks, guard rotating parts, and avoid run-dry conditions

Q50. A major merit of Silverson emulsifiers compared to low-shear mixers is:

- Lower initial equipment cost always

- Ability to rapidly produce fine, stable emulsions with controlled droplet size

- They never require maintenance

- They are ineffective for viscous systems

Correct Answer: Ability to rapidly produce fine, stable emulsions with controlled droplet size

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com