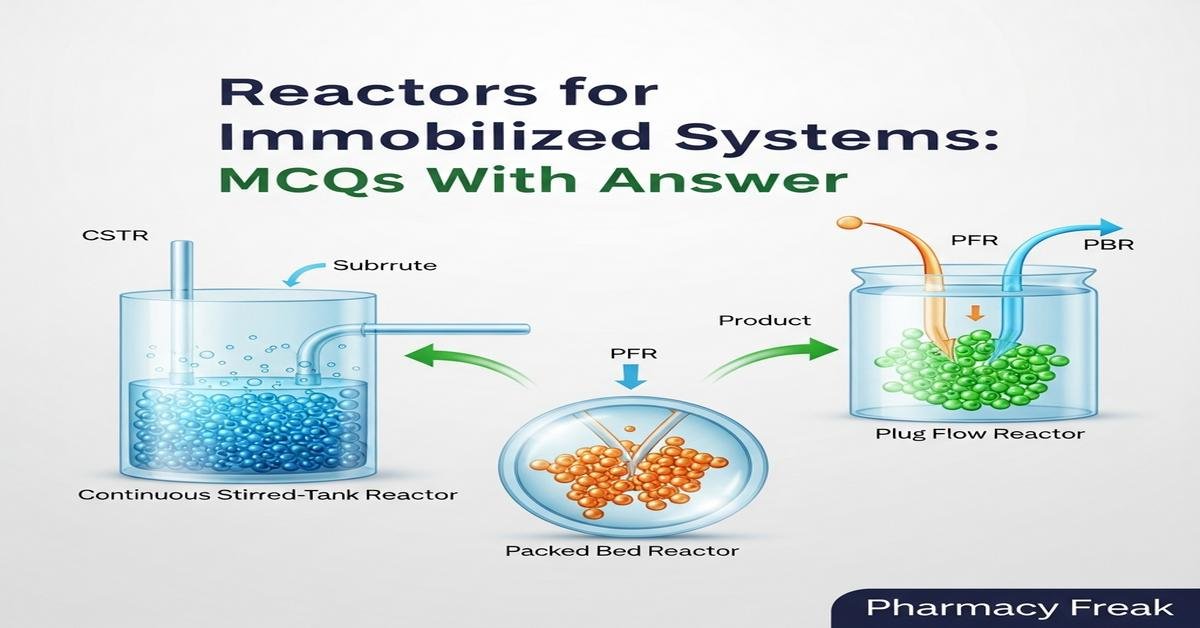

This quiz set covers “Reactors for immobilized systems” tailored for M.Pharm students studying Bioprocess Engineering and Technology. It reviews reactor types (packed bed, fluidized bed, stirred reactors with carriers, membrane reactors), transport and kinetic limitations in immobilized matrices, design principles like plug-flow and CSTR behavior, mass transfer resistances (external and internal), Thiele modulus and effectiveness factor, and practical scale-up considerations. Each question emphasizes mechanistic understanding and application to pharmaceutical bioprocesses such as enzyme- or cell-immobilized production. Use these MCQs to test conceptual clarity, prepare for exams, and strengthen problem-solving for designing and operating immobilized bioreactors in drug manufacturing.

Q1. Which of the following is the primary advantage of using immobilized-cell or immobilized-enzyme reactors in pharmaceutical bioprocesses?

- Elimination of all mass transfer limitations

- High cell concentration and reusability leading to increased volumetric productivity

- Complete prevention of microbial contamination without sterilization

- Unlimited operational temperature range

Correct Answer: High cell concentration and reusability leading to increased volumetric productivity

Q2. In a packed-bed reactor (PBR) with immobilized enzyme beads, the term “effectiveness factor” refers to:

- The ratio of observed overall reaction rate to the rate if the enzyme were uniformly dispersed with no internal diffusion resistance

- The fraction of bed volume occupied by beads

- The pressure drop per unit length of the bed

- The porosity of individual beads

Correct Answer: The ratio of observed overall reaction rate to the rate if the enzyme were uniformly dispersed with no internal diffusion resistance

Q3. The Thiele modulus is a dimensionless number used to characterize:

- The ratio of external mass transfer to enzyme activity

- The relative magnitude of internal diffusion resistance to reaction rate inside porous catalyst/biocatalyst particles

- The compressibility of packed beds under flow

- The degree of shear-induced cell damage in stirred immobilized systems

Correct Answer: The relative magnitude of internal diffusion resistance to reaction rate inside porous catalyst/biocatalyst particles

Q4. Which reactor type most closely approximates plug-flow behavior for immobilized catalysts in continuous operation?

- Well-mixed stirred-tank reactor with suspended carriers

- Packed-bed reactor with low axial dispersion

- Batch reactor with immobilized beads

- Continuous stirred-tank cascade with many stages

Correct Answer: Packed-bed reactor with low axial dispersion

Q5. External film mass transfer resistance in immobilized particle systems can be minimized by:

- Increasing particle diameter while keeping other conditions constant

- Decreasing bulk fluid velocity to reduce shear

- Increasing agitation or superficial velocity to reduce boundary layer thickness

- Using larger pore sizes to increase internal diffusion only

Correct Answer: Increasing agitation or superficial velocity to reduce boundary layer thickness

Q6. For immobilized enzymes inside spherical beads, if the Thiele modulus >> 1, the system is typically:

- Reaction-limited with negligible diffusion resistance

- Diffusion-limited with significant internal mass transfer resistance

- Operated under vacuum to enhance transport

- Independent of particle size

Correct Answer: Diffusion-limited with significant internal mass transfer resistance

Q7. Which of the following is NOT a typical advantage of fluidized-bed reactors for immobilized cell/particle systems?

- Improved external mass transfer due to particle movement

- Low pressure drop compared to packed beds

- Uniform temperature control and reduced channeling

- Complete elimination of particle attrition at high gas velocities

Correct Answer: Complete elimination of particle attrition at high gas velocities

Q8. In designing an immobilized-cell reactor for an aerobic bioprocess, the critical consideration specific to immobilization is:

- Ensuring excess nitrogen supply to the medium

- Providing adequate oxygen transfer through the matrix to the cells

- Minimizing light penetration into the reactor

- Maximizing ionic strength of the buffer

Correct Answer: Providing adequate oxygen transfer through the matrix to the cells

Q9. Which design equation best describes an ideal packed-bed reactor behavior when axial dispersion is negligible?

- Batch kinetic equation

- Plug flow reactor (PFR) model

- Well-mixed continuous stirred-tank reactor (CSTR) model

- Two-phase multi-compartment model only

Correct Answer: Plug flow reactor (PFR) model

Q10. A common consequence of immobilized-cell leakage from beads in long-term operation is:

- Complete sterilization of the reactor

- Increase in free-cell contamination and possible loss of immobilized capacity

- Enhanced immobilized particle stability

- Reduction of substrate uptake by the bulk phase only

Correct Answer: Increase in free-cell contamination and possible loss of immobilized capacity

Q11. Which property of support matrix most strongly influences internal diffusion of substrate to immobilized biocatalyst?

- Mechanical strength only

- Pore size distribution and tortuosity

- Color and opacity

- Electrical conductivity

Correct Answer: Pore size distribution and tortuosity

Q12. The Ergun equation is used in packed-bed reactor design primarily to estimate:

- Thiele modulus inside particles

- Pressure drop across the packed bed as a function of flow and particle size

- Enzyme deactivation rate constant

- Effectiveness factor for internal diffusion

Correct Answer: Pressure drop across the packed bed as a function of flow and particle size

Q13. When immobilized enzymes in beads swell appreciably upon hydration, this most directly affects:

- External bulk fluid viscosity only

- Effective diffusivity and pore structure inside the beads

- Gas solubility in the bulk phase exclusively

- Temperature dependence of enzyme kinetics only

Correct Answer: Effective diffusivity and pore structure inside the beads

Q14. For immobilized systems, the observed decrease in KLa (volumetric oxygen transfer coefficient) compared with free-cell suspension is commonly due to:

- Increased interfacial area from immobilized beads

- Barrier to oxygen diffusion into microenvironments around cells or beads

- Higher gas holdup only

- Complete elimination of boundary layers

Correct Answer: Barrier to oxygen diffusion into microenvironments around cells or beads

Q15. In modelling immobilized-enzyme reactors using Michaelis–Menten kinetics with internal diffusion, which modification is typically required?

- Replace Vmax with apparent Vmax that includes internal diffusion limitations (effectiveness factor)

- Ignore substrate concentration gradients entirely

- Assume first-order kinetics irrespective of substrate concentration

- Use gas-phase mass balances only

Correct Answer: Replace Vmax with apparent Vmax that includes internal diffusion limitations (effectiveness factor)

Q16. Which operational strategy helps reduce channeling in a packed-bed immobilized reactor?

- Using a monodisperse bead size with poor bed packing

- Introducing flow distributors and appropriate particle packing to ensure uniform flow distribution

- Operating at extremely low Reynolds numbers to stop mixing

- Removing all bed support screens to maximize space

Correct Answer: Introducing flow distributors and appropriate particle packing to ensure uniform flow distribution

Q17. During scale-up of an immobilized packed-bed reactor, maintaining geometric similarity alone is often insufficient because:

- Kinetic parameters change with reactor volume only

- Hydrodynamics, mass transfer coefficients, and pressure drop scale differently and affect performance

- Bead chemistry becomes inert at larger scales

- Temperature has no effect at pilot scale

Correct Answer: Hydrodynamics, mass transfer coefficients, and pressure drop scale differently and affect performance

Q18. A membrane reactor for immobilized enzymes provides what key advantage over a conventional packed-bed reactor?

- Complete elimination of diffusion resistance inside particles

- Selective removal or retention of products/substrates and reduced washout of biocatalyst

- Lower initial capital cost in all cases

- No need for control of operating conditions

Correct Answer: Selective removal or retention of products/substrates and reduced washout of biocatalyst

Q19. In an immobilized-cell stirred tank using entrapped cells, increasing the stirrer speed excessively may cause:

- Reduced external mass transfer

- Mechanical shear damage to cells and particle breakage

- Lower oxygen transfer coefficients

- Increased bead porosity without damage

Correct Answer: Mechanical shear damage to cells and particle breakage

Q20. When evaluating an immobilized biocatalyst, “operational stability” primarily refers to:

- The ability to withstand extreme pH for a few seconds

- The retained catalytic activity and mechanical integrity of the immobilized system over repeated or continuous use

- The initial burst activity only

- Total absence of microbial contamination forever

Correct Answer: The retained catalytic activity and mechanical integrity of the immobilized system over repeated or continuous use

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com