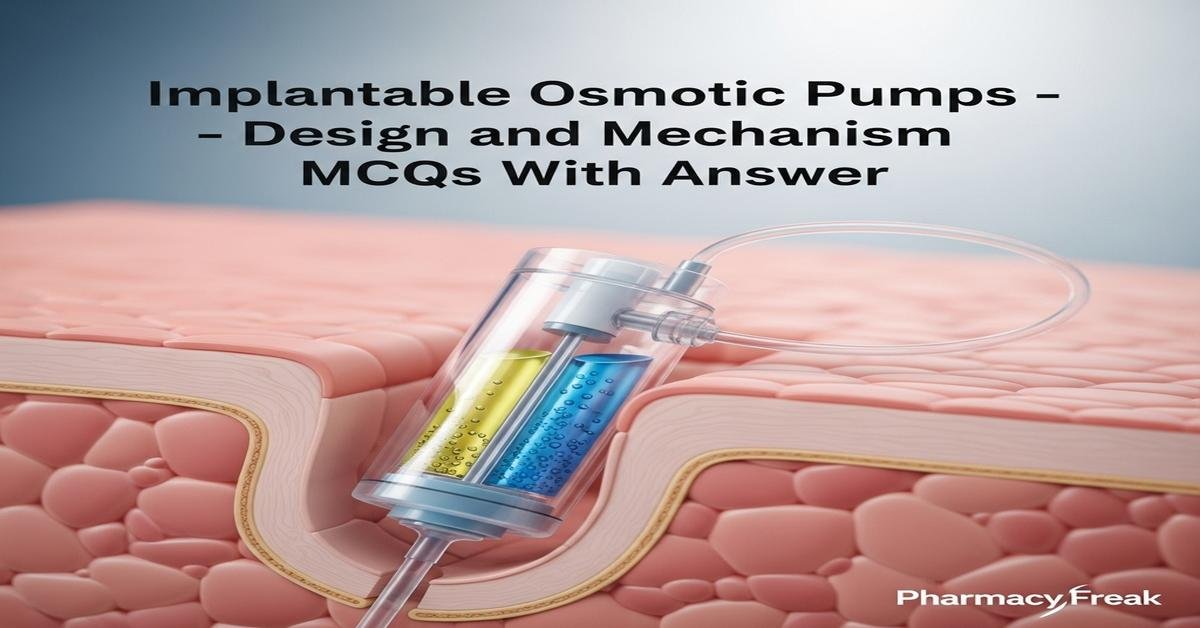

Implantable osmotic pumps are small, controlled-drug delivery devices widely studied in B.Pharm curricula. They rely on an osmotic engine and a semipermeable membrane to generate a constant infusion rate, enabling zero-order release of small molecules, peptides, and hormones over days to months. Key design elements include the drug reservoir, semipermeable membrane, osmotic agent, and flow moderator; critical factors affecting performance are membrane permeability, osmotic gradient, drug solubility, device geometry, and backpressure. Understanding mechanism, materials (cellulose acetate, polymers), failure modes, sterilization, and in vitro–in vivo correlation is essential for formulation and evaluation. Now let’s test your knowledge with 30 MCQs on this topic.

Q1. Which component in an implantable osmotic pump primarily generates the driving force for drug release?

- Drug reservoir

- Semipermeable membrane

- Osmotic agent (osmotic engine)

- Flow moderator (orifice)

Correct Answer: Osmotic agent (osmotic engine)

Q2. The release profile most commonly associated with a well-designed osmotic pump is:

- First-order release

- Zero-order release

- Burst followed by exponential decay

- Immediate release

Correct Answer: Zero-order release

Q3. Which material is frequently used as a semipermeable membrane in osmotic pumps?

- Polyethylene glycol (PEG)

- Cellulose acetate

- Polylactic acid (PLA)

- Silicone rubber

Correct Answer: Cellulose acetate

Q4. Increase in membrane thickness of a semipermeable membrane will most likely:

- Increase osmotic flux and speed up release

- Decrease water influx and slow down drug release

- Have no effect on release rate

- Cause immediate dose dumping

Correct Answer: Decrease water influx and slow down drug release

Q5. In an osmotic pump, the flow moderator primarily:

- Generates osmotic pressure

- Maintains sterility of the reservoir

- Controls the exit rate of drug solution from the reservoir

- Serves as a biodegradable scaffold

Correct Answer: Controls the exit rate of drug solution from the reservoir

Q6. Which factor will NOT directly affect the osmotic pressure driving an implantable osmotic pump?

- Concentration of osmotic agent inside the pump

- External tissue osmolarity

- Temperature of the surrounding tissue

- Drug molecular weight (if fully soluble)

Correct Answer: Drug molecular weight (if fully soluble)

Q7. Which of the following describes a “push–pull” osmotic pump design?

- A single reservoir with immediate release coating

- Two-chamber system where one chamber swells to push drug from the other

- A membrane-less diffusion device

- A pump that requires external activation

Correct Answer: Two-chamber system where one chamber swells to push drug from the other

Q8. For poorly water-soluble drugs, which formulation strategy in an osmotic pump can help maintain desired release?

- Use of a hydrophobic membrane only

- Create a suspension without solubilizers

- Include solubilizers or convert drug to salt form

- Decrease osmotic agent concentration

Correct Answer: Include solubilizers or convert drug to salt form

Q9. Which in vitro test is most relevant to evaluate performance of an implantable osmotic pump?

- Dissolution testing under sink conditions with controlled osmotic gradient

- Swelling index in organic solvents

- Dry weight loss in ambient air

- Viscosity of the device polymer melt

Correct Answer: Dissolution testing under sink conditions with controlled osmotic gradient

Q10. Which statement about semipermeable membranes in osmotic pumps is TRUE?

- They allow drug molecules but block water

- They allow water but restrict solute passage

- They are fully permeable to all molecules

- They actively pump fluid using mechanical action

Correct Answer: They allow water but restrict solute passage

Q11. Which failure mode can cause sudden uncontrolled release (dose dumping) from an osmotic pump?

- Membrane fouling by proteins

- Crystallization of osmotic agent

- Membrane rupture or breach

- Slow swelling of osmotic engine

Correct Answer: Membrane rupture or breach

Q12. The DUROS implant is best described as:

- An oral osmotic tablet

- A transdermal patch

- A surgically implantable osmotic pump for long-term delivery

- An inhalable nanoparticle system

Correct Answer: A surgically implantable osmotic pump for long-term delivery

Q13. Which mathematical relationship is commonly used to estimate osmotic pressure in dilute solutions relevant to pump design?

- Henderson–Hasselbalch equation

- van ’t Hoff equation

- Nernst equation

- Arrhenius equation

Correct Answer: van ’t Hoff equation

Q14. How does backpressure at the outlet affect drug release from an osmotic pump?

- Higher backpressure increases release rate

- Backpressure has no effect

- Higher backpressure decreases release rate

- Backpressure turns pump into a first-order system

Correct Answer: Higher backpressure decreases release rate

Q15. Which sterilization method is often avoided for protein-loaded implantable osmotic pumps due to denaturation risk?

- Gamma irradiation

- Ethylene oxide sterilization

- Sterile filtration of components

- Autoclaving (steam sterilization)

Correct Answer: Autoclaving (steam sterilization)

Q16. What is the role of an orifice in many osmotic pump designs?

- Permit water influx only

- Provide a defined path for drug efflux and control flow resistance

- Store osmotic agent

- Act as a biodegradable plug that swells

Correct Answer: Provide a defined path for drug efflux and control flow resistance

Q17. Which parameter should be measured to establish in vitro–in vivo correlation (IVIVC) for an implantable osmotic pump?

- Surface color change over time

- In vitro release rate and plasma concentration–time profile

- Device tensile strength

- Osmotic agent taste

Correct Answer: In vitro release rate and plasma concentration–time profile

Q18. Which drug class is especially well-suited for delivery by implantable osmotic pumps?

- Drugs requiring immediate high peak concentrations only

- Short half-life drugs needing frequent dosing (e.g., peptides)

- Highly volatile anesthetics

- Drugs unstable in aqueous environment

Correct Answer: Short half-life drugs needing frequent dosing (e.g., peptides)

Q19. Which design change would most likely increase drug release rate from an osmotic pump?

- Decrease osmotic agent concentration

- Increase membrane permeability

- Thicken the semipermeable membrane

- Reduce the area of the semipermeable membrane

Correct Answer: Increase membrane permeability

Q20. Which regulatory consideration is critical for implantable osmotic pumps?

- Color matching with skin tones

- Biocompatibility and ISO 10993 testing

- Packaging aroma

- Oral bioavailability studies only

Correct Answer: Biocompatibility and ISO 10993 testing

Q21. The term “osmotic engine” in an implantable pump refers to:

- The mechanical motor that runs on batteries

- The compartment containing a high-concentration osmotic agent that generates swelling pressure

- The drug formulation itself

- The exterior coating that resists protein adhesion

Correct Answer: The compartment containing a high-concentration osmotic agent that generates swelling pressure

Q22. Which profiling outcome indicates ideal zero-order release from an osmotic pump during in vitro testing?

- Drug release proportional to square root of time

- Linear cumulative amount released versus time

- Log cumulative amount released versus time linearity

- Exponential decline in release rate

Correct Answer: Linear cumulative amount released versus time

Q23. What effect does increasing the osmotic agent concentration inside the pump have, assuming membrane permeability constant?

- Decrease osmotic pressure and slow release

- Increase osmotic pressure and increase release rate

- No change in release behavior

- Convert zero-order to first-order kinetics

Correct Answer: Increase osmotic pressure and increase release rate

Q24. Which material property is most important for the reservoir wall to prevent drug–polymer interaction?

- Electrical conductivity

- Chemical inertness and compatibility

- High thermal conductivity

- Porosity to solutes

Correct Answer: Chemical inertness and compatibility

Q25. In vivo, protein adsorption on the membrane surface can cause:

- Increased water flux and faster release

- Membrane fouling that reduces permeability and slows release

- Immediate disintegration of the device

- No impact at all on release

Correct Answer: Membrane fouling that reduces permeability and slows release

Q26. A common analytical method to quantify drug released from an osmotic pump during testing is:

- UV–Vis spectrophotometry or HPLC analysis of release medium

- Scanning electron microscopy of the device surface

- Thermogravimetric analysis of the reservoir

- pH meter of dried device

Correct Answer: UV–Vis spectrophotometry or HPLC analysis of release medium

Q27. Which statement about miniaturized implantable osmotic pumps for animal studies is correct?

- They always use the same design as human implants

- They are scaled to provide appropriate dose rates for small animals

- They cannot achieve zero-order release

- They are implanted orally in the stomach

Correct Answer: They are scaled to provide appropriate dose rates for small animals

Q28. The selection of osmotic agent (e.g., salt vs. polymeric osmogen) influences:

- Only device color

- Magnitude and duration of osmotic pressure generated

- The electrical power source needed

- Ability to be delivered via inhalation

Correct Answer: Magnitude and duration of osmotic pressure generated

Q29. Which design feature helps prevent microbial contamination of the drug reservoir in an implantable osmotic pump?

- Large external vents to tissue

- Sterile fabrication, sealed reservoirs, and biocompatible barriers

- Perforated membrane that allows bacteria to pass

- Adding sugar to the reservoir

Correct Answer: Sterile fabrication, sealed reservoirs, and biocompatible barriers

Q30. When formulating a highly viscous drug solution for an osmotic pump, a potential design consideration is:

- Decrease orifice resistance to accommodate higher viscosity

- Increase membrane thickness to slow water entry further

- Remove the osmotic agent completely

- Use a membrane that blocks water entirely

Correct Answer: Decrease orifice resistance to accommodate higher viscosity

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com