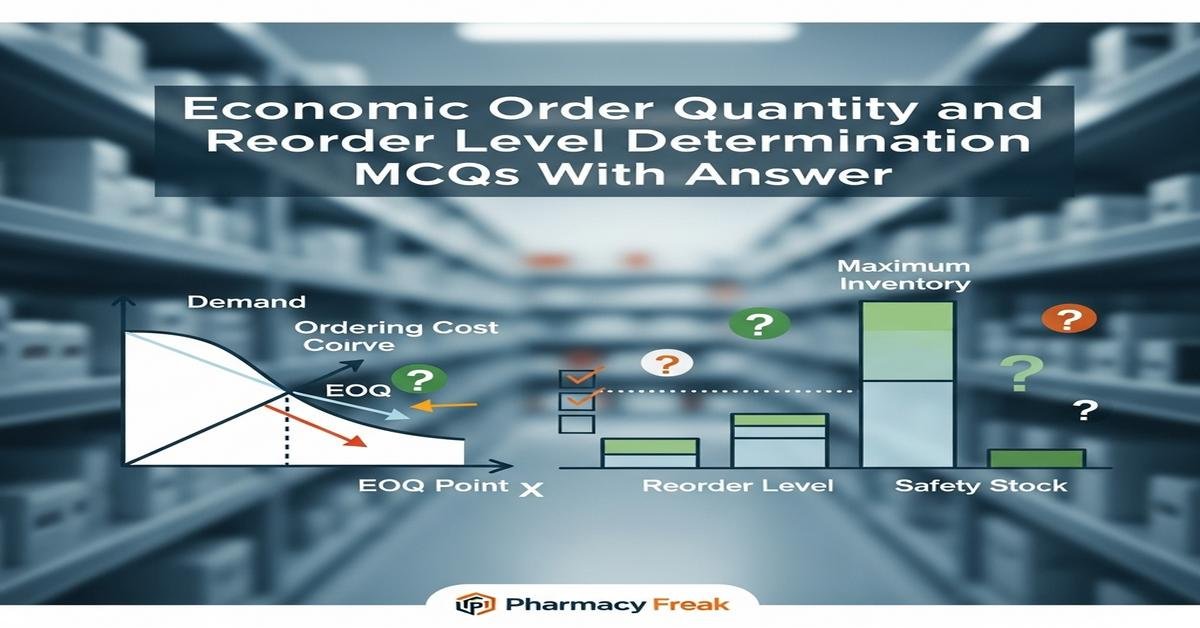

Inventory control in pharmaceutical practice relies on tools like Economic Order Quantity (EOQ) and Reorder Level to balance service and cost. EOQ determines the optimal order size that minimizes total inventory cost (ordering plus holding), while reorder level (reorder point) tells when to place an order considering lead time and safety stock. B. Pharm students should master EOQ calculations, carrying cost, ordering cost, lead-time demand, safety stock, service levels, and expiry-driven constraints unique to medicines. Strong knowledge reduces stockouts, wastage and supports regulatory compliance in pharmacy inventory management. Now let’s test your knowledge with 30 MCQs on this topic.

Q1. What is the Economic Order Quantity (EOQ)?

- Order quantity that minimizes total inventory cost (ordering + holding)

- Maximum stock level that can be stored in the pharmacy

- Daily consumption rate multiplied by lead time

- Number of batches produced per year

Correct Answer: Order quantity that minimizes total inventory cost (ordering + holding)

Q2. Which formula represents the classical EOQ model?

- EOQ = sqrt(2DS/H)

- EOQ = (D x H) / (2S)

- EOQ = D / (S + H)

- EOQ = Sqrt(D / (2SH))

Correct Answer: EOQ = sqrt(2DS/H)

Q3. Which assumption is NOT part of the basic EOQ model?

- Constant and known demand

- Instantaneous replenishment (zero lead time)

- No quantity discounts on purchase

- Lead time and demand are highly variable and random

Correct Answer: Lead time and demand are highly variable and random

Q4. What is the reorder level (reorder point)?

- The inventory level at which a new order should be placed to avoid stockouts during lead time

- The maximum storage capacity of the warehouse

- The minimum economic batch that can be ordered from a supplier

- The average monthly consumption of an item

Correct Answer: The inventory level at which a new order should be placed to avoid stockouts during lead time

Q5. Which expression gives the basic reorder level (without safety stock)?

- Reorder Level = Average daily demand × Lead time (in days)

- Reorder Level = EOQ / 2

- Reorder Level = Annual demand / Number of orders

- Reorder Level = Safety stock − Lead time

Correct Answer: Reorder Level = Average daily demand × Lead time (in days)

Q6. What is the main purpose of safety stock in pharmacy inventory?

- To act as a buffer against demand or lead time variability and prevent stockouts

- To increase the EOQ value artificially

- To reduce ordering costs by ordering less frequently

- To extend the shelf life of medicines

Correct Answer: To act as a buffer against demand or lead time variability and prevent stockouts

Q7. Which of the following costs is typically included in annual holding (carrying) cost?

- Insurance, storage, obsolescence and capital opportunity cost

- Purchase order processing fees

- Freight-in charged by the supplier

- Quality testing charges per batch

Correct Answer: Insurance, storage, obsolescence and capital opportunity cost

Q8. Which cost is considered an ordering (setup) cost in EOQ analysis?

- Costs of placing and receiving an order such as paperwork, inspection and transport

- Interest on capital invested in inventory

- Temperature-controlled storage expenses

- Costs due to expired medicines

Correct Answer: Costs of placing and receiving an order such as paperwork, inspection and transport

Q9. If lead time increases while demand remains constant, what happens to the reorder level?

- Reorder level increases

- Reorder level decreases

- Reorder level remains unchanged

- EOQ becomes zero

Correct Answer: Reorder level increases

Q10. If the ordering cost (S) increases, what is the effect on EOQ (other factors constant)?

- EOQ increases

- EOQ decreases

- EOQ remains the same

- EOQ becomes equal to annual demand

Correct Answer: EOQ increases

Q11. If annual holding cost per unit (H) increases, how does EOQ change?

- EOQ decreases

- EOQ increases

- EOQ remains unaffected

- EOQ becomes negative

Correct Answer: EOQ decreases

Q12. How does product perishability (expiry) affect EOQ and inventory policy in a pharmacy?

- Perishability usually reduces optimal order quantity and increases review frequency to avoid wastage

- Perishability increases EOQ because larger batches reduce unit cost

- Perishability has no impact on ordering decisions

- Perishability eliminates the need for safety stock

Correct Answer: Perishability usually reduces optimal order quantity and increases review frequency to avoid wastage

Q13. Continuous review (Q) system is best characterized by which of the following?

- Inventory is monitored continuously and orders are placed when inventory falls to the reorder point

- Orders are placed at fixed time intervals regardless of stock level

- All items are ordered in fixed monthly amounts only

- Inventory is reviewed annually to set one replenishment

Correct Answer: Inventory is monitored continuously and orders are placed when inventory falls to the reorder point

Q14. For normally distributed demand during lead time, safety stock is commonly calculated as:

- Safety stock = z × standard deviation of demand during lead time

- Safety stock = average demand × lead time

- Safety stock = EOQ / 2

- Safety stock = ordering cost / holding cost

Correct Answer: Safety stock = z × standard deviation of demand during lead time

Q15. Calculate EOQ: Annual demand = 5,000 units, ordering cost = Rs.100 per order, annual holding cost per unit = Rs.5. What is EOQ (approx)?

- 447 units

- 1,000 units

- 223 units

- 5,000 units

Correct Answer: 447 units

Q16. If average daily demand = 20 units, lead time = 5 days and safety stock = 10 units, what is the reorder level?

- 110 units

- 100 units

- 50 units

- 20 units

Correct Answer: 110 units

Q17. Average weekly demand = 70 units, lead time = 2 weeks, safety stock = 10 units. What is the reorder point?

- 150 units

- 70 units

- 140 units

- 10 units

Correct Answer: 150 units

Q18. Economic Production Quantity (EPQ) differs from EOQ because EPQ assumes:

- Replenishment occurs gradually during production rather than instant receipt

- Demand is zero during production runs

- Holding costs are zero

- No setup or ordering costs exist

Correct Answer: Replenishment occurs gradually during production rather than instant receipt

Q19. How do quantity discounts offered by suppliers affect EOQ analysis?

- They may lower total cost and lead to ordering larger than classical EOQ after total cost comparison

- They always increase EOQ regardless of discount size

- They make EOQ formula invalid and therefore useless

- They never affect ordering strategy because purchase price is ignored

Correct Answer: They may lower total cost and lead to ordering larger than classical EOQ after total cost comparison

Q20. In ABC analysis for pharmacy stocks, which statement is true?

- Class A items are high value with tight control and frequent review

- Class A items are the least important and rarely monitored

- Class B items are always perishable and require no safety stock

- Class C items should be ordered monthly regardless of demand

Correct Answer: Class A items are high value with tight control and frequent review

Q21. Which cost is usually excluded from the EOQ basic formula?

- Purchase cost per unit

- Ordering cost

- Holding cost

- Setup cost

Correct Answer: Purchase cost per unit

Q22. When demand is highly variable, the most direct way to reduce stockouts is to:

- Increase safety stock or improve service level targets

- Reduce holding cost per unit

- Increase ordering cost artificially

- Always order exactly EOQ regardless of variation

Correct Answer: Increase safety stock or improve service level targets

Q23. Service level in inventory management typically refers to:

- The probability of not running out of stock during the lead time

- The percentage of items past expiry

- The number of days between orders

- The supplier’s on-time delivery rate only

Correct Answer: The probability of not running out of stock during the lead time

Q24. Increased lead time variability generally requires:

- Higher safety stock to maintain the same service level

- Lower reorder level to save costs

- Smaller EOQ to discourage ordering

- Elimination of safety stock

Correct Answer: Higher safety stock to maintain the same service level

Q25. Annual holding cost per unit (H) is best described as:

- The total cost to hold one unit in inventory for one year (storage, capital, obsolescence)

- The cost to place one purchase order

- The purchase price of one unit only

- The revenue lost due to stockouts

Correct Answer: The total cost to hold one unit in inventory for one year (storage, capital, obsolescence)

Q26. Total annual inventory cost typically includes:

- Purchase cost + Ordering cost + Holding cost

- Only holding cost and supplier profit

- Only ordering and inspection costs

- Salaries of pharmacists only

Correct Answer: Purchase cost + Ordering cost + Holding cost

Q27. If lead time is zero (instant replenishment), what is the reorder point?

- Zero

- Equal to EOQ

- Equal to annual demand

- Equal to safety stock only

Correct Answer: Zero

Q28. Which action most effectively reduces the required safety stock for a given service level?

- Reduce lead time variability (or reduce lead time)

- Increase ordering cost

- Reduce demand forecasting accuracy

- Increase EOQ without changing lead time

Correct Answer: Reduce lead time variability (or reduce lead time)

Q29. When determining order quantities for pharmaceuticals, which additional factor is vital compared with general retail?

- Expiry/shelf life and stability constraints

- Color of packaging

- Supplier logo design

- Number of competing brands only

Correct Answer: Expiry/shelf life and stability constraints

Q30. Which stock rotation policy is most important in pharmacy to minimize expiry-related losses?

- FIFO (First-In, First-Out)

- LIFO (Last-In, First-Out)

- Random rotation

- Always use the newest stock first

Correct Answer: FIFO (First-In, First-Out)

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com