Cartridge filter – principle, construction, working, uses, merits, demerits MCQs With Answer

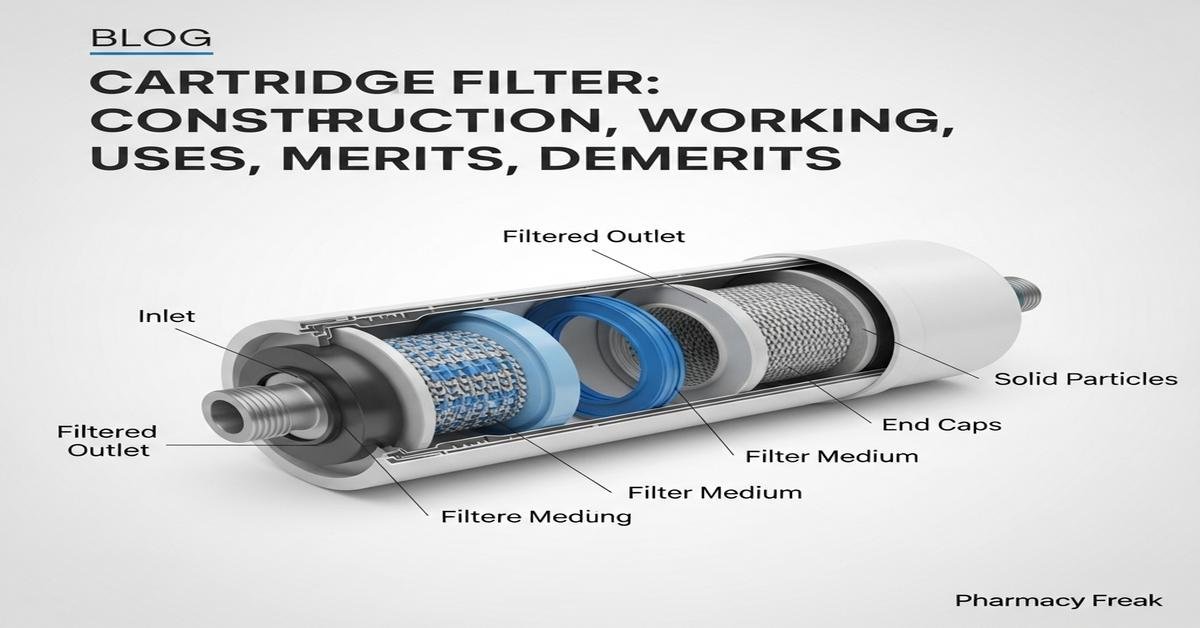

Cartridge filters are essential in pharmaceutical processing for particle removal, sterile filtration and sample clarification. This introduction explains the principle (surface vs depth filtration), construction (housing, end caps, media types like membrane, pleated and depth), working parameters (pore size, flow, differential pressure, integrity tests), common uses in B. Pharm labs (sterile parenteral filtration, water purification, solvent clarification), merits (high efficiency, modularity) and demerits (fouling, limited lifespan, solvent compatibility issues). Keywords: cartridge filter, principle, construction, working, uses, merits, demerits, MCQs, B. Pharm students. Now let’s test your knowledge with 50 MCQs on this topic.

Q1. What is the primary principle by which a cartridge filter removes particles?

- Solvent adsorption

- Size exclusion and mechanical straining

- Centrifugal separation

- Chemical reaction

Correct Answer: Size exclusion and mechanical straining

Q2. Which pore size is commonly used for sterile filtration of pharmaceutical solutions?

- 10 µm

- 0.8 µm

- 0.45 µm

- 0.22 µm

Correct Answer: 0.22 µm

Q3. Which of the following is a membrane material commonly used for cartridge filters in sterile applications?

- Polyvinylidene fluoride (PVDF)

- Polystyrene

- Polyethylene terephthalate (PET) only

- Glass wool

Correct Answer: Polyvinylidene fluoride (PVDF)

Q4. What does “depth filtration” mean in cartridge filters?

- Filtration using membrane sheets only

- Particles are retained throughout the thickness of the media

- Filtration by adsorption to activated carbon

- Only surface particles are retained on a membrane

Correct Answer: Particles are retained throughout the thickness of the media

Q5. Which test is commonly used to check the integrity of sterilizing-grade membrane cartridges?

- pH test

- Bubble point test

- Viscosity measurement

- Thermogravimetric analysis

Correct Answer: Bubble point test

Q6. Nominal vs absolute ratings refer to what aspect of cartridge filters?

- Mechanical strength under pressure

- Degree of particle retention consistency

- Chemical compatibility with solvents

- Color of the filter media

Correct Answer: Degree of particle retention consistency

Q7. Which cartridge filter type is most suitable for removing fine colloidal particles?

- Pleated depth cartridge

- Wire mesh screen

- Coarse bag filter

- Sand filter

Correct Answer: Pleated depth cartridge

Q8. What is a common disadvantage of cartridge filters in continuous processing?

- Infinite lifetime

- They require frequent replacement due to fouling

- They add nutrients to formulations

- They generate large heat during use

Correct Answer: They require frequent replacement due to fouling

Q9. Which filter material is hydrophobic and often used for gas or solvent filtration?

- Cellulose acetate

- Nylon 6,6

- Polytetrafluoroethylene (PTFE)

- Glass fiber

Correct Answer: Polytetrafluoroethylene (PTFE)

Q10. What parameter increases as a cartridge filter becomes clogged during operation?

- Permeate flow rate

- Differential pressure across the filter

- Pore size

- Transmembrane temperature

Correct Answer: Differential pressure across the filter

Q11. Which cartridge filter configuration provides a high surface area for increased flow and capacity?

- Plain flat disc

- Pleated cartridge

- Solid rod

- Woven mesh cylinder

Correct Answer: Pleated cartridge

Q12. Which of the following is NOT a typical use of cartridge filters in pharmaceutical manufacturing?

- Sterile filtration of parenteral solutions

- Clarification before chromatography

- Bulk cooling of reaction mixtures

- Final polishing of water for injection

Correct Answer: Bulk cooling of reaction mixtures

Q13. What is the main role of a prefilter or coarse cartridge upstream of a fine cartridge?

- Increase product viscosity

- Capture larger particles to extend life of the fine cartridge

- Sterilize the fluid completely

- Neutralize pH

Correct Answer: Capture larger particles to extend life of the fine cartridge

Q14. Which parameter is essential when selecting a cartridge filter for solvent compatibility?

- Filter color

- Filter housing brand

- Chemical resistance of the media and gasket

- Ambient humidity only

Correct Answer: Chemical resistance of the media and gasket

Q15. Sterilizing-grade cartridge filters are validated to remove which of the following?

- Bacteria and most bacterial spores

- All viruses and pyrogens

- Bacteria and bacterial cells (but not necessarily viruses)

- Only visible particles larger than 50 µm

Correct Answer: Bacteria and bacterial cells (but not necessarily viruses)

Q16. What does the term “retention rating” of a cartridge filter describe?

- The maximum temperature the filter can withstand

- The smallest particle size retained at a specified efficiency

- The weight of the cartridge

- The time it takes to install the filter

Correct Answer: The smallest particle size retained at a specified efficiency

Q17. Which cleaning method is commonly used for reusable cartridge housings (not disposable cartridges)?

- Autoclaving the cartridge media always

- CIP (clean-in-place) of the housing and replacement of disposable cartridges

- Boiling in water for 5 minutes

- Soaking in strong acids without compatibility checks

Correct Answer: CIP (clean-in-place) of the housing and replacement of disposable cartridges

Q18. In pharmaceutical filtration, what is the main difference between “absolute” and “nominal” filter ratings?

- Absolute indicates guaranteed retention at a stated size; nominal indicates approximate performance

- Nominal is always better than absolute

- Absolute refers to color; nominal refers to shape

- There is no difference

Correct Answer: Absolute indicates guaranteed retention at a stated size; nominal indicates approximate performance

Q19. Which integrity test is more suitable than visual inspection to ensure a membrane is intact after sterilization?

- Bubble point or diffusion test

- Checking cartridge color

- Measuring pH of permeate only

- Weight measurement

Correct Answer: Bubble point or diffusion test

Q20. Which gasket material is commonly used in cartridges when compatibility with organic solvents is required?

- Nitrile (Buna-N)

- EPDM (ethylene propylene diene monomer)

- Viton (fluoroelastomer)

- Natural rubber

Correct Answer: Viton (fluoroelastomer)

Q21. What effect does decreasing pore size have on filter performance, assuming same surface area and flow conditions?

- Increases contaminant passage

- Decreases pressure drop across the filter

- Increases retention efficiency but increases pressure drop or reduces flow

- Has no effect

Correct Answer: Increases retention efficiency but increases pressure drop or reduces flow

Q22. Which cartridge filter type is best for high-viscosity fluids where depth cake formation is a concern?

- High-capacity depth cartridge with graded porosity

- Very fine membrane with small pores only

- Open wire mesh only

- Uncontained loose media

Correct Answer: High-capacity depth cartridge with graded porosity

Q23. Which statement about pyrogens (endotoxins) and cartridge filtration is correct?

- Typical 0.22 µm filters reliably remove dissolved endotoxins

- Pyrogens are soluble and often require specific removal methods beyond simple filtration

- All cartridge filters are pyrogen-free by default

- Endotoxins are always larger than 1 µm so are easily filtered

Correct Answer: Pyrogens are soluble and often require specific removal methods beyond simple filtration

Q24. For sterile filtration of heat-sensitive parenterals, what is the preferred approach?

- Use high-temperature thermal sterilization instead of filtration

- Use a validated 0.22 µm sterilizing-grade cartridge filter under aseptic conditions

- Rely on dilution to reduce microbial counts

- Filter through a 10 µm filter only

Correct Answer: Use a validated 0.22 µm sterilizing-grade cartridge filter under aseptic conditions

Q25. Which feature of a cartridge filter housing is important for pharmaceutical GMP compliance?

- Transparent color for aesthetics

- Material of construction compatible with cleaning and sterilization (e.g., stainless steel)

- Single-use cardboard housing

- Open top design without seals

Correct Answer: Material of construction compatible with cleaning and sterilization (e.g., stainless steel)

Q26. What is meant by “filter blow-out” in cartridge housings?

- Controlled release of filtered product

- Failure of cartridge end cap or seal allowing unfiltered fluid to bypass

- Purposeful venting of air during installation

- Normal operation during backwash

Correct Answer: Failure of cartridge end cap or seal allowing unfiltered fluid to bypass

Q27. Which cartridge material is preferred for low protein-binding when filtering proteinaceous formulations?

- Cellulose ester

- Hydrophilic PVDF or low-binding PES

- Activated carbon

- PTFE hydrophobic membrane

Correct Answer: Hydrophilic PVDF or low-binding PES

Q28. Which operational parameter should be monitored regularly to determine the end-of-life for a cartridge filter?

- Differential pressure and reduced permeate flow rate

- Ambient light intensity

- Color of the housing only

- Operator’s mood

Correct Answer: Differential pressure and reduced permeate flow rate

Q29. In pharmaceutical sample preparation, why are syringe cartridge filters used?

- To concentrate large volumes rapidly

- To remove particulate matter prior to HPLC or assay to protect analytical columns

- To sterilize large batches of solution

- To change pH of samples

Correct Answer: To remove particulate matter prior to HPLC or assay to protect analytical columns

Q30. Which is a key merit of cartridge filters compared to depth beds or sand filters?

- Lower initial cost for very large flows always

- Easy installation, predictable performance and replaceability

- They never need replacement

- They are effective for high-temperature incineration

Correct Answer: Easy installation, predictable performance and replaceability

Q31. Which factor most directly affects the flux (flow per unit area) through a membrane cartridge?

- Operator’s handwriting

- Pore size, fluid viscosity and transmembrane pressure

- Ambient room color

- Brand of filter only

Correct Answer: Pore size, fluid viscosity and transmembrane pressure

Q32. What is the typical reason for choosing a 0.45 µm filter instead of a 0.22 µm filter in a process step?

- To achieve sterile filtration

- For clarification and particulate removal where bacterial retention is not required, and higher flow is desired

- To remove viruses

- Because 0.45 µm filters are always cheaper to manufacture

Correct Answer: For clarification and particulate removal where bacterial retention is not required, and higher flow is desired

Q33. Which of the following is a demerit specifically associated with membrane cartridges when exposed to incompatible solvents?

- Improved filtration efficiency

- Membrane swelling, degradation or loss of integrity

- Becoming self-sterilizing

- Automatically increasing pore size uniformly

Correct Answer: Membrane swelling, degradation or loss of integrity

Q34. How is bacterial retention typically demonstrated during validation of a sterilizing filter?

- By measuring turbulence in the housing

- By microbial challenge tests using specific bacteria and log reduction value measurements

- By checking the filter color post-use

- By tasting the filtrate

Correct Answer: By microbial challenge tests using specific bacteria and log reduction value measurements

Q35. Which cartridge design feature helps minimize channeling and bypass in pleated cartridges?

- Loose end-cap fit

- Proper end-cap molding, gaskets and centralized support cores

- Using no support core

- Omitting seals around housings

Correct Answer: Proper end-cap molding, gaskets and centralized support cores

Q36. For filtration of organic solvents like methanol, which membrane is often preferred due to chemical compatibility?

- Hydrophilic cellulose ester

- Hydrophobic PTFE or compatible PVDF depending on solvent

- Paper filter

- Uncoated glass fiber only

Correct Answer: Hydrophobic PTFE or compatible PVDF depending on solvent

Q37. What is the main functional difference between a cartridge filter and a packed-bed absorbent?

- Cartridge filters provide mechanical size-based separation; packed beds provide adsorption-based removal

- Cartridge filters are only used for gases

- Packed beds are single-use only

- There is no functional difference

Correct Answer: Cartridge filters provide mechanical size-based separation; packed beds provide adsorption-based removal

Q38. Which validation activity is most relevant after installing new cartridge filter housings?

- Media color matching

- Leak test and installation qualification (IQ) and operational qualification (OQ)

- Measuring filter weight

- Replacing all gaskets with cotton

Correct Answer: Leak test and installation qualification (IQ) and operational qualification (OQ)

Q39. Which property makes hydrophilic membranes preferable for aqueous pharmaceutical formulations?

- They repel water

- They wet easily with water facilitating consistent flux and reduced air entrapment

- They dissolve in water

- They are electrically conductive

Correct Answer: They wet easily with water facilitating consistent flux and reduced air entrapment

Q40. What is the likely consequence of using a filter with an inappropriate gasket material?

- Improved microbial retention

- Chemical incompatibility leading to leaks, contamination or gasket failure

- Automatic cleaning of the system

- No effect at all

Correct Answer: Chemical incompatibility leading to leaks, contamination or gasket failure

Q41. Which filtration mode is most applicable when a cartridge is used to remove large particles before final sterile filtration?

- Sterilizing grade filtration

- Prefiltration or coarse filtration

- Adsorptive polishing only

- Reverse osmosis

Correct Answer: Prefiltration or coarse filtration

Q42. Which is a correct statement about autoclaving cartridge filters?

- All cartridge filters can be autoclaved regardless of material

- Only cartridges specified as autoclaveable by the manufacturer should be autoclaved

- Autoclaving always improves filter life

- Autoclaving is never used in pharma

Correct Answer: Only cartridges specified as autoclaveable by the manufacturer should be autoclaved

Q43. What is an important consideration when storing unused cartridge filters in a GMP environment?

- Store them in direct sunlight to sterilize

- Store per manufacturer instructions in clean, dry conditions and sealed packaging

- Store in open bins to allow dust accumulation

- Freeze them at -80°C

Correct Answer: Store per manufacturer instructions in clean, dry conditions and sealed packaging

Q44. Which measurement helps quantify particle removal efficiency of a cartridge filter during development?

- Particle size distribution and log reduction values for target sizes

- Operator height

- Colorimetric pH only

- Electrical resistance of housing

Correct Answer: Particle size distribution and log reduction values for target sizes

Q45. When is a stainless-steel cartridge housing preferred over a plastic housing?

- When aesthetics are the main concern

- When high pressure, high temperature, or solvent compatibility and cleanability are required

- When single-use waste reduction is not important

- When cost must be minimized regardless of process needs

Correct Answer: When high pressure, high temperature, or solvent compatibility and cleanability are required

Q46. What is the typical effect of pleating on filter media?

- Reduces surface area

- Increases surface area, improving capacity and flow

- Makes the filter impermeable

- Eliminates the need for end caps

Correct Answer: Increases surface area, improving capacity and flow

Q47. Which parameter is NOT directly influenced by filter cartridge pore size?

- Retention of particles of a given size

- Permeate clarity

- Color of the filter housing

- Flow resistance (for same area)

Correct Answer: Color of the filter housing

Q48. During pharmaceutical filtration, why is it important to monitor total organic carbon (TOC) in filtered water?

- TOC indicates microbial counts directly

- TOC is irrelevant in pharmaceutical water systems

- High TOC may indicate organic contamination that cartridge filters may not remove and may support microbial growth

- TOC determines filter pore size

Correct Answer: High TOC may indicate organic contamination that cartridge filters may not remove and may support microbial growth

Q49. Which of the following is an advantage of single-use cartridge filter systems in certain pharmaceutical operations?

- They require complex cleaning validation

- They reduce cross-contamination risk and cleaning/validation burden

- They always cost less over many years

- They are difficult to qualify

Correct Answer: They reduce cross-contamination risk and cleaning/validation burden

Q50. What is the appropriate action if a sterilizing-grade cartridge fails the bubble point test after installation?

- Continue filtration because visual clarity is sufficient

- Remove and replace the cartridge and investigate cause before resuming sterile processing

- Increase flow to compensate

- Ignore and document nothing

Correct Answer: Remove and replace the cartridge and investigate cause before resuming sterile processing

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com