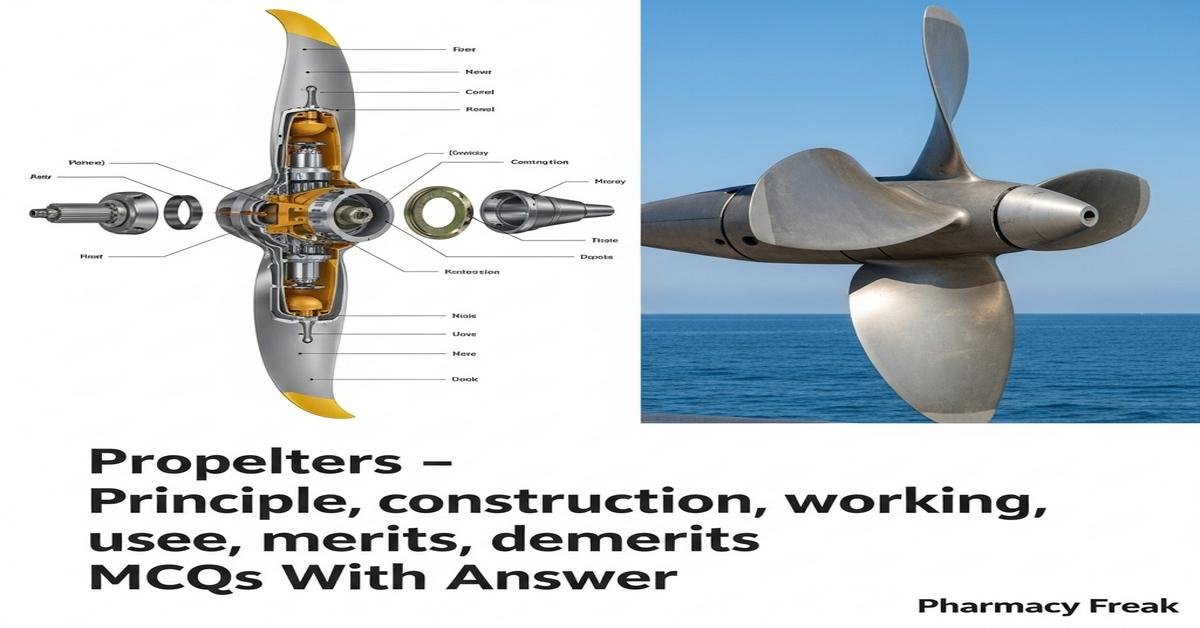

Introduction: Propellers are widely used impellers in pharmaceutical mixing, employed for blending, suspension, and homogenization of low-to-moderate viscosity liquids. This concise guide explains propellers – principle, construction, working, uses, merits, demerits to help B. Pharm students understand their role in unit operations, scale-up and formulation processes. Learn how blade design, pitch, hub geometry and rotational speed influence axial flow, shear, solids suspension and process efficiency. Practical examples cover selection for suspensions, emulsions and dilution steps, along with cleaning, material choices and limitations in high-viscosity systems. Now let’s test your knowledge with 50 MCQs on this topic.

Q1. What is the primary flow pattern generated by a standard propeller impeller used in pharmaceutical mixers?

- Axial flow

- Radial flow

- Tangential flow

- Oscillatory flow

Correct Answer: Axial flow

Q2. Which component is NOT part of a typical propeller construction?

- Hub

- Blades

- Paddle shaft seal

- Combustion chamber

Correct Answer: Combustion chamber

Q3. What is the main advantage of propeller impellers in pharmaceutical mixing?

- High axial pumping and efficient mixing of low-viscosity fluids

- Best performance for very high-viscosity pastes

- Generate high shear suitable for particle size reduction

- Eliminate need for baffles in all tanks

Correct Answer: High axial pumping and efficient mixing of low-viscosity fluids

Q4. Which material is most commonly used for propeller blades in sterile pharmaceutical processes?

- Stainless steel (SS316)

- Carbon steel without coating

- Aluminum alloy

- Brass

Correct Answer: Stainless steel (SS316)

Q5. How does increasing blade pitch of a propeller affect flow?

- Increases axial flow and pumping

- Reduces axial flow and increases radial flow

- Has no effect on flow

- Converts flow to oscillatory motion

Correct Answer: Increases axial flow and pumping

Q6. For which pharmaceutical operation is a propeller impeller typically preferred?

- Mixing of low-viscosity solutions and suspensions

- Mixing of very high-viscosity creams and pastes

- Solid tablet coating inside drum coaters

- Dry powder blending in V-blenders

Correct Answer: Mixing of low-viscosity solutions and suspensions

Q7. What is a common disadvantage of propeller impellers?

- Poor performance in high-viscosity fluids

- Excessive shear for delicate suspensions

- Inability to be cleaned

- Produce only radial flow

Correct Answer: Poor performance in high-viscosity fluids

Q8. Which flow characteristic aids in suspending particles using a propeller?

- Axial up-and-down circulation promoting bulk flow

- Purely tangential swirl

- Localized laminar layers only

- No net circulation

Correct Answer: Axial up-and-down circulation promoting bulk flow

Q9. Which design change increases mixing without significantly increasing shear?

- Using a larger diameter propeller at lower speed

- Sharpening blade edges to slicing profile

- Increasing rotational speed drastically

- Adding serrated teeth to blades

Correct Answer: Using a larger diameter propeller at lower speed

Q10. In scale-up, which parameter is often conserved to maintain similar flow patterns for propellers?

- Geometric similarity and tip speed or power per volume depending on objective

- Keeping rotor color same as lab model

- Operating at identical rpm regardless of tank size

- Using the same motor brand

Correct Answer: Geometric similarity and tip speed or power per volume depending on objective

Q11. Which type of propeller blade angle generally produces stronger axial flow?

- Moderate pitch (20–40°)

- Zero pitch (flat blades)

- Very low angle (<5°)

- Reversed curvature only

Correct Answer: Moderate pitch (20–40°)

Q12. What is the role of baffles when using propellers in tanks?

- Prevent vortex formation and improve mixing efficiency

- Increase vortex depth for better aeration

- Reduce contact surface area for heat transfer

- Serve as decorative elements only

Correct Answer: Prevent vortex formation and improve mixing efficiency

Q13. Propeller impellers are least suitable for which process?

- Mixing heavy pastes and high-viscosity gels

- Suspending light powders in water

- Dissolving salts into water

- General agitation of aqueous formulations

Correct Answer: Mixing heavy pastes and high-viscosity gels

Q14. Which measurement indicates the non-dimensional performance of an impeller and depends on Reynolds number?

- Power number

- Blade length in cm

- Motor brand

- Tank color

Correct Answer: Power number

Q15. What effect does increasing impeller diameter (relative to tank) have on mixing?

- Increases pumping capacity and circulation

- Always causes decreased mixing

- Makes mixing purely radial

- Eliminates need for motor

Correct Answer: Increases pumping capacity and circulation

Q16. Why are propellers favored for gas dispersion in some applications?

- They create axial flow that promotes gas-liquid contact in low-viscosity systems

- They generate maximum shear to break gas bubbles instantly

- They prevent gas from dissolving

- They immobilize bubbles at the surface

Correct Answer: They create axial flow that promotes gas-liquid contact in low-viscosity systems

Q17. Which clinical pharmaceutical process commonly uses propeller mixers?

- Preparation of suspensions and solutions in liquid dosage manufacturing

- Compression of tablets in high-speed presses

- Coating C of solid forms using rotary coatings

- Lyophilization trays mixing

Correct Answer: Preparation of suspensions and solutions in liquid dosage manufacturing

Q18. What is cavitation and why is it a concern for propellers?

- Vapor bubble formation at blade tips causing noise, erosion and performance loss

- Formation of solid deposits on blades improving efficiency

- Intentional bubble formation for sterilization

- Permanent magnetization of blades

Correct Answer: Vapor bubble formation at blade tips causing noise, erosion and performance loss

Q19. Which cleaning requirement is essential for propellers in aseptic pharmaceutical operations?

- Smooth surface finish and CIP/SIP compatibility

- Rough textured blades for better adhesion

- Painted surfaces to prevent corrosion

- Non-sterilizable plastic coatings

Correct Answer: Smooth surface finish and CIP/SIP compatibility

Q20. How does tip speed relate to shear generation in propeller mixing?

- Higher tip speed increases shear and potential for degradation

- Tip speed has no effect on shear

- Lower tip speed always causes more shear

- Tip speed affects only temperature not shear

Correct Answer: Higher tip speed increases shear and potential for degradation

Q21. Which propeller design modification reduces shear while maintaining flow?

- Increasing blade area and reducing rpm

- Adding sharp serrations to blades

- Decreasing blade area and increasing rpm

- Using brittle materials for blades

Correct Answer: Increasing blade area and reducing rpm

Q22. What is the typical application of pitched-blade propellers compared to flat-blade ones?

- Pitched blades produce stronger axial flow suitable for bulk circulation

- Pitched blades always produce radial flow only

- Flat blades are used for gas-liquid dispersion exclusively

- Pitched blades are unsuitable for pharma

Correct Answer: Pitched blades produce stronger axial flow suitable for bulk circulation

Q23. In terms of energy, propeller impellers are generally:

- Energy-efficient for low-viscosity fluids (lower power consumption)

- Extremely power-hungry for all fluids

- Always use more power than turbines

- Require no energy input

Correct Answer: Energy-efficient for low-viscosity fluids (lower power consumption)

Q24. Which factor most directly affects solids suspension capability of a propeller?

- Impeller diameter, speed, and clearance from tank bottom

- Tank wall color

- Operator height

- Time of day when mixing

Correct Answer: Impeller diameter, speed, and clearance from tank bottom

Q25. For low-shear mixing of shear-sensitive proteins, a suitable choice is:

- Large diameter propeller running at low rpm

- Very small propeller at high rpm

- Serrated high-shear turbine

- High-speed homogenizer

Correct Answer: Large diameter propeller running at low rpm

Q26. Which propeller characteristic improves gas-liquid mass transfer in aeration applications?

- Creating axial flow and recirculation to disperse gas

- Minimizing flow to keep gas at surface

- Eliminating recirculation entirely

- Using color-coded blades

Correct Answer: Creating axial flow and recirculation to disperse gas

Q27. What is the effect of a higher number of blades on a propeller?

- Increases flow smoothness but may reduce efficiency at same rpm

- Always increases cavitation risk drastically

- Makes blade cleaning impossible

- Has no effect on performance

Correct Answer: Increases flow smoothness but may reduce efficiency at same rpm

Q28. Which impeller would you select for dispersing a liquid into another liquid (emulsification) requiring moderate shear?

- Propeller with moderate tip speed

- Large slow paddle with no shear

- Only static mixers, never propellers

- High-shear rotor-stator exclusively

Correct Answer: Propeller with moderate tip speed

Q29. Which maintenance consideration is important for propellers in pharma plants?

- Periodic inspection for erosion, balance and seal integrity

- Never inspect to avoid contamination

- Replace blades daily regardless of condition

- Paint blades monthly

Correct Answer: Periodic inspection for erosion, balance and seal integrity

Q30. What design feature minimizes dead zones in tank mixing with propellers?

- Appropriate impeller placement and baffles

- Using the smallest possible impeller at top center

- Removing all baffles to create swirl

- Operating at zero rpm periodically

Correct Answer: Appropriate impeller placement and baffles

Q31. Which process parameter is reduced when propellers are run at lower rpm but larger diameter is used?

- Shear stress while maintaining similar flow

- Bulk circulation always reduces to zero

- Temperature increases drastically

- CIP effectiveness is lost

Correct Answer: Shear stress while maintaining similar flow

Q32. What is the likely consequence of operating a propeller too close to tank walls?

- Increased wear and lower hydraulic efficiency

- Improved mixing with no downsides

- Guaranteed sterile conditions

- Instant scale-up success

Correct Answer: Increased wear and lower hydraulic efficiency

Q33. Which cleaning feature is desirable for pharmaceutical propellers to avoid cross-contamination?

- Polished surfaces and crevice-free welds

- Deep grooves to trap residues

- Textured paint coatings

- Non-removable hubs

Correct Answer: Polished surfaces and crevice-free welds

Q34. Which of the following best describes power consumption trend for propellers as viscosity increases?

- Power requirement increases significantly, reducing efficiency

- Power requirement decreases with viscosity

- Power stays constant regardless of viscosity

- Propellers convert power into cooling

Correct Answer: Power requirement increases significantly, reducing efficiency

Q35. Which operational change helps suspend heavier particles when using a propeller?

- Increase impeller clearance from tank bottom slightly and increase rpm

- Reduce impeller diameter drastically

- Lower rpm to near zero

- Remove baffles entirely

Correct Answer: Increase impeller clearance from tank bottom slightly and increase rpm

Q36. What is an appropriate use of propeller mixers in sterile filling lines?

- Mixing bulk sterile solutions in closed vessels designed for CIP/SIP

- Direct mixing inside sterile fill nozzles

- As primary sterilizers replacing autoclaves

- For final sterile filtration

Correct Answer: Mixing bulk sterile solutions in closed vessels designed for CIP/SIP

Q37. In terms of scale-up criteria, which approach may be chosen to preserve mixing intensity for propellers?

- Constant power per unit volume (P/V)

- Keeping same rpm irrespective of scale

- Always matching impeller color

- Using smallest motor available

Correct Answer: Constant power per unit volume (P/V)

Q38. Which safety concern is particularly relevant when operating high-speed propellers?

- Mechanical failure and blade fragmentation risk

- Immediate sterilization of contents

- Spontaneous formation of active pharmaceutical ingredient

- Automatic viscosity reduction

Correct Answer: Mechanical failure and blade fragmentation risk

Q39. What is the effect of impeller off-center mounting on mixing?

- Creates uneven flow, increased vibration and poor mixing

- Always improves mixing uniformly

- Makes seals last longer

- Has no practical effect

Correct Answer: Creates uneven flow, increased vibration and poor mixing

Q40. For particle wetting and dispersion in liquid formulation, propellers are effective when:

- Used with appropriate speed and dispersion aids in low-viscosity media

- Used only in high-viscosity gels

- Blades are removed during dispersion

- No agitation is performed

Correct Answer: Used with appropriate speed and dispersion aids in low-viscosity media

Q41. Which statement about axial flow propellers versus radial turbines is correct?

- Axial propellers give bulk circulation, turbines give high shear and radial flow

- Axial propellers always generate more shear than turbines

- Radial turbines are preferred for low-viscosity bulk mixing

- They are identical in all applications

Correct Answer: Axial propellers give bulk circulation, turbines give high shear and radial flow

Q42. What is a practical way to reduce foaming when using propellers for aerated systems?

- Use lower rpm, antifoam agents or specialized impellers

- Increase rpm to maximum to burst bubbles

- Remove all mixing to allow natural foam settling

- Change tank color to dark

Correct Answer: Use lower rpm, antifoam agents or specialized impellers

Q43. Which inspection technique is useful to detect imbalance in propeller blades?

- Vibration analysis and dynamic balancing

- Smelling the blade for imbalance

- Only visual inspection while running at full speed

- Weighing blades in the dark

Correct Answer: Vibration analysis and dynamic balancing

Q44. Which design parameter is most critical to avoid dead zones below the impeller?

- Proper impeller-substrate clearance and impeller diameter

- Using the thinnest possible shaft regardless of length

- Minimizing blade width only

- Increasing operating temperature only

Correct Answer: Proper impeller-substrate clearance and impeller diameter

Q45. What is the recommended finish for propeller surfaces in sterile pharmaceutical service?

- Electropolished smooth finish

- Rough blasted finish

- Unfinished cut metal surface

- Painted textured finish

Correct Answer: Electropolished smooth finish

Q46. Which operational adjustment helps when propellers cause too much shear on sensitive APIs?

- Decrease rpm and increase impeller diameter (lower tip speed)

- Increase rpm further to reduce shear

- Switch to serrated high-shear blades

- Freeze the tank contents

Correct Answer: Decrease rpm and increase impeller diameter (lower tip speed)

Q47. What is an expected merit of propellers compared with high-shear mixers?

- Lower shear generation and better energy efficiency for bulk mixing

- Always produce finer emulsions than high-shear mixers

- Require no maintenance

- Provide sterilization during mixing

Correct Answer: Lower shear generation and better energy efficiency for bulk mixing

Q48. In a tank with two-stage mixing, where is a propeller often placed?

- As a stage for bulk circulation often combined with another impeller type for shear

- Always at the very top rim only

- Only outside the tank

- Directly above the motor to cool it

Correct Answer: As a stage for bulk circulation often combined with another impeller type for shear

Q49. Which factor most influences tip vortex formation in propellers?

- Tip clearance, blade design and operating speed

- Impeller color and brand

- Temperature alone without speed change

- Number of operators in the room

Correct Answer: Tip clearance, blade design and operating speed

Q50. When comparing propellers and pitched-blade turbines for a formulation requiring both circulation and moderate shear, the best choice is often:

- Use a propeller for circulation paired with a pitched-blade turbine or combine impeller types

- Only use static mixers without mechanical impellers

- Use the smallest propeller at highest rpm only

- Operate without impellers for natural mixing

Correct Answer: Use a propeller for circulation paired with a pitched-blade turbine or combine impeller types

I am a Registered Pharmacist under the Pharmacy Act, 1948, and the founder of PharmacyFreak.com. I hold a Bachelor of Pharmacy degree from Rungta College of Pharmaceutical Science and Research. With a strong academic foundation and practical knowledge, I am committed to providing accurate, easy-to-understand content to support pharmacy students and professionals. My aim is to make complex pharmaceutical concepts accessible and useful for real-world application.

Mail- Sachin@pharmacyfreak.com